Size effect of AlGaInP red micro-LEDs on silicon substrate

Micro-LEDs have been used in many fields due to their superior performance, such as micro-displays, visible light communication, optical biochips, wearable devices, and biosensors. Obtaining high resolution and high pixel density is one of the key technical challenges of working with micro-LED array displays, as it requires smaller and smaller chip sizes and pixel pitches.

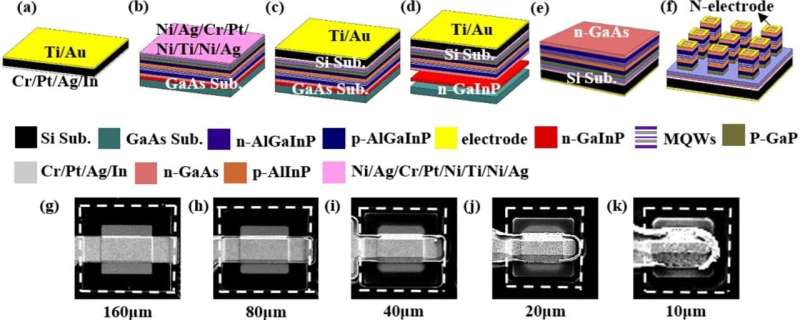

In a study published in Results in Physics, a research group led by Prof. Liang Jingqiu from the Changchun Institute of Optics, Fine Mechanics and Physics (CIOMP) of the Chinese Academy of Sciences investigated the size effect of aluminum gallium indium phosphide (AlGaInP) red Micro-LEDs on silicon substrate.

The researchers adopted a low-damage etching formula and silicon substrates with better heat dissipation to avoid the light absorption properties of GaAs substrates.

Experimental results show that smaller micro-LEDs have smaller leakage current and larger series resistance and can withstand higher current density without the current crowding effect.

Due to the larger perimeter-to-area ratio of small-sized micro-LEDs, non-radiative recombination increases, which leads to a lower external quantum efficiency. But smaller micro-LEDs can alleviate the problem of the high-current efficiency droop.

In addition, because of a better heat dissipation under a high injection current, smaller micro-LEDs (<80 μm) have a smaller center wavelength shift.

It is worth noting that the measured local minimum ideal factor is consistent for different chip sizes. This indicates that the size effect caused by process technology can be suppressed by sidewall treatment.

Under the condition of constant current density, the edge of the smaller micro-LED chip is brighter, because the current spread length of the smaller micro-LED is relatively large, resulting in higher current density at the boundary.

AlGaInP red micro-LEDs prepared on silicon substrate with low damage etching formula can suppress the size effect caused by the process. These experimental results provide important basis for the design and manufacture of red micro-LEDs with different pixel sizes.

More information: Kaili Fan et al, Size effects of AlGaInP red vertical micro-LEDs on silicon substrate, Results in Physics (2022). DOI: 10.1016/j.rinp.2022.105449

Provided by Chinese Academy of Sciences