New carbon nanotube technology to reduce large-scale emissions

A novel technology to trap large-scale greenhouse gas emissions caused by coal mining and power generation is being developed by a University of Queensland researcher.

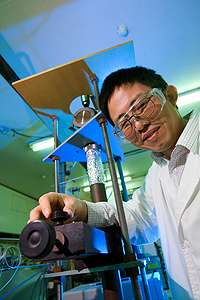

Dr John Zhu, Senior Lecturer in the School of Engineering, aims to develop a carbon nanotube (CNT) membrane for gas separation that will work like a sieve to separate high volumes of methane or carbon dioxide from other gases.

Dr Zhu said that the CNT technology was exciting because it would trap moving gases up to 100 times faster than other gas separation techniques and could therefore be used by large-scale plants such as power stations.

“Conventional membranes such as polymeric and metal membranes, porous silica and carbon molecular sieves all show a trade-off between how well they separate gases and how much gas they can process,” he said.

“The CNT membranes can both separate effectively and process large volumes of gas, making them superior to conventional membranes at the large scale required for coal-fired power plants or natural gas processing.

“If the technology is successful, it may be able to significantly reduce the amount of greenhouse gases produced through power generation. This is especially important in Queensland where we are dependent on power generated from coal.”

The carbon nanotube technology works by “sieving” gas as it passes through the membrane, and can be applied to various aspects of the power-generation process including during the mining process and after the fuel is burnt.

During underground coal mining, methane (an explosive gas which is present in the coal) must be removed before the coal can be extracted. In current practice, the methane is so diluted with air that it cannot be used and is therefore released into the atmosphere. The CNT membrane will enable the methane to be separated and harnessed for use as valuable pipeline quality gas.

In power stations, after coal or gas is burnt, a CNT membrane may be used to separate carbon dioxide from waste gas. The carbon dioxide can then be permanently and safely disposed of through methods such as sequestration.

If successful, the CNT membrane is likely to be commercialised and available for use in the next 10 to 15 years.

Dr Zhu said he was both pleased and grateful that his research was being recognised by the University with the award, and for the opportunity to advance research in an area so critical to the future health of the planet.

“I have been concerned about humankind's impact on the environment for many years. It is imperative that we reduce greenhouse emissions. I hope the CNT membrane will help to achieve that,” Dr Zhu said.

Source: UQ