April 21, 2006 feature

Rigiflex lithography improves organic LEDs

In the race to create the roll-up TV (and a host of other devices), scientists are continually manipulating organic light-emitting diode (OLED) technology. Recently, researchers from Korea have designed a technique that is rigid enough to allow extremely high resolution and flexible enough to cover a large area in a simple process.

Because OLED technology is one of the newer methods to enter the flat panel display market, analysts initially predicted that OLED would have some catching up to do to compete with the popularity of LEDs, LCDs (liquid crystal devices) and plasma screens. However, scientists are meeting the technical challenges of OLEDs and designing technology that proves its worth in many regards: it’s brighter, faster, lighter, cheaper, bigger and smaller than other technologies in certain areas.

OLEDs, like LEDs, are electroluminescent, meaning they generate light when electrically stimulated. As opposed to LEDs that use semiconductors to enable electron-hole recombination, OLEDs use carbon-based molecules (which vary depending on desired color). However, the two most prominent OLED techniques have limitations: the pattern transfer method has color constraints, and the shadow mask method can only cover small areas.

In a recent issue of Nanotechnology, scientists Jun-ho Choi et al. present a simple and effective method for OLED displays using rigiflex lithography, a technique that members of the team introduced last year.

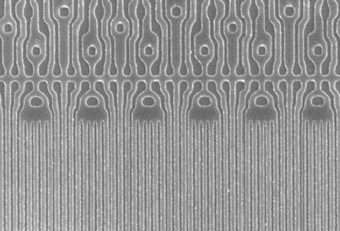

“While the rigid nature of the rigiflex mould allows resolution down to the sub-100 nm range, the flexible nature of the mould makes it possible for the transfer to be applied to large areas,” wrote the scientists. “A flat substrate is not necessarily flat in that there is always roughness at the nanometer scale if not the micrometer level….A flexible mould can make intimate contact with the underlying surface over a large area because of the flexibility, which makes large area applications possible.”

To enable large area applications, the method uses low pressure for the transfer of a mold made of poly (urethane acrylate) (PUA). After depositing organic multilayers on the mold, the design is transferred to a glass-coated (indium tin oxide) surface by a simple process based on the adhesion difference between the mold and the surface.

Compared with other OLED techniques, rigiflex lithography demonstrates equivalent luminance strength, but outperformed other techniques with its large size, flexibility and simplicity. The method allows a simple step-and-repeat transfer of each color (red, green and blue) OLED.

“There is no particular limit on the size in principle,” Hong Lee, coauthor, told PhysOrg.com. “With rigiflex OLED, you can 'print' the whole device in one process, whereas with other techniques, you have to do it one at a time, many times for many layers involved in the fabrication.”

Applications for OLED technology currently under investigation include "smart" light-emitting shades; video walls; and electronic displays on clothes, windshields and visors for pilots, drivers and scuba divers.

Citation: Choi, Jun-ho, Kim, Kyung-Ho, Choi, Se-Jin and Lee, Hong H. Whole device printing for full colour displays with organic light emitting diodes. Nanotechnology 17 (2006) 2246-2249.

By Lisa Zyga, Copyright 2006 PhysOrg.com