Fibonacci series on microstructures

It is a big challenge for materials scientists to produce highly ordered micro- and nanostructures in a designed pattern with uniform size and shape. By controlling the geometry and the stress upon cooling, CAS researchers coaxed a microstructure to self-assemble into the triangular tessellation and Fibonacci number patterns on its surface. Their work 'Triangular and Fibonacci number patterns driven by stress on core/shell microstructures' was published on the August 5 issue of Science.

Fibonacci patterns come from a numerical sequence that fascinated the Italian mathematician Leonardo Fibonacci in the early 1200s. Each entry of the sequence is obtained by adding the two previous numbers together: 0, 1, 1, 2, 3, 5, 8, 13, 21, 34, 55, 89, 144.... The patterns have been noted to frequently appear in biological settings, like the spiral arrangement of the florests, seeds, sepals and scales on such plants as pinecones, pineapples and sunflowers. For instance, people may find two sets of lines connecting the centers of each segment of the pinecone, 13 in clockwise and 8 in counterclockwise; or, in terms of sunflower spirals, the combinations can be in 21 by 34, 34 by 55 until 89 by 144.

Using a core of silver and a shell of silicon oxide, Prof. Cao Zexian, together with his colleagues Li Chaorong and Zhang Xiaonan from the CAS Institute of Physics, set out on examining stresses in a microstructure about 10 micrometres in diameter. They first heated a mixture of Ag2O and SiO onto a substrate held at 1270 K, a temperature just above the melting point of silver but below that for SiO2, and then let the system cool down step by step. The researchers discovered that the shell shrank much less than the core, and bumpy patterns appeared on the shell as a result. These bumps appeared in different patterns with markedly uniform size and shape, depending on the geometry of the primary supporting surface.

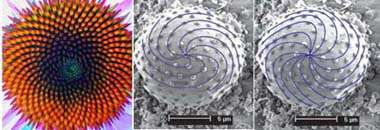

A coneflower showing 21x34 Fibonacci spirals at the primordium (left), and stress pattern on a flattened Ag core/SiO2 shell structure that can be grouped into 8 clockwise and 13 countclockwise spirals (center and right).

For a spherical microstructure, a uniform triangular pattern appeared, containing some defects to enable it to cover a spherical surface - these took the form of five- or seven-fold triangles around a vertex. For conical microstructures, on the other hand, cooling led to the formation of the bumps in a spiral pattern, which were arranged in two sets of spirals, running in opposite directions. Curiously, the numbers of spirals in each pair of spiral sets were always adjacent members of the Fibonacci series. The researchers found sets with 5 by 8, 8 by 13, and 13 by 21 spirals.

This is the first time that the triangular tessellation and Fibonacci number patterns have been grown with inorganic materials on a micrometre scale, according to the CAS researchers. They further revealed the formation mechanism and conditions for the patterns on the basis of an analysis on their structural characteristics. "From our results we see that it is the geometry of the supporting surface, on which the stress strives for a minimal strain energy, that tips the formation of patterns," says Prof. Cao. It is speculated that "The various seemingly different patterns for botanic elements such as sepals, seeds, and florets can be explained by the unique mechanism to minimize the total strain energy under a given geometric constraint, without resorting to any genetic or biochemical factors."

The technology could find a use in the mass-production of mesoscale structures over a large area, according to researchers. It demonstrated that highly ordered patterns can be fabricated on core/shell structures through stress-driven self-assembly induced by controlled cooling. The patterns obtained on nonplanar surfaces "... may be of importance in applications such as photonic crystals, since scattering events at such sites will show some coherence, and technologically it sidesteps the difficult intentional introduction of defects.

Source: The Chinese Academy of Sciences