Carbon Nanotube 'Shock Absorbers' Excel at Dampening Vibration

Research on a new class of nanostructured materials used to reduce vibrations in mechanical equipment and electronic devices, being developed by a team of scientists at Rensselaer Polytechnic Institute, will be featured in Nature Materials.

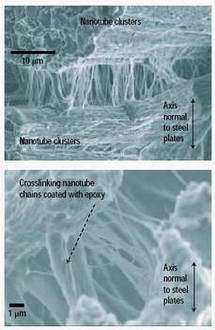

This image shows clusters of the carbon-nanotube vibration-dampening material. Credit: Nikhil Koratkar, Rensselaer Polytechnic Institute.

“The nanoscale building blocks we have developed have both micro and macro applications,” said Nikhil Koratkar, assistant professor of mechanical, aerospace, and nuclear engineering at Rensselaer. “The new systems reduce and control vibrations within structures and will benefit the performance, safety, and reliability of future manufacturing equipment, sensitive laboratory equipment, and everyday electronic devices.”

The Rensselaer research team, led by Koratkar, added carbon nanotube fillers to traditional vibration reduction materials to enhance their energy dissipation capability. Adding large quantities of nanoscale fillers increases the amount of surface area, and thereby increases frictional sliding that occurs at the filler-to-filler interface. The result is a decrease in vibrations.

In 2004, Koratkar received a National Science Foundation (NSF) Faculty Early Career Development Award (CAREER) to fund the development of these new materials. Additional Rensselaer researchers on the project include Pulickel Ajayan, professor of materials science and engineering; Pawel Keblinksi, associate professor of materials science and engineering; and Jonghwan Suhr, a doctoral student in mechanical, aerospace, and nuclear engineering.

The research is available in the Nature Materials journal online, and will be published in an upcoming print edition of the journal.

Source: Rensselaer Polytechnic Institute