Mini-laboratory gets megaproductive

(PhysOrg.com) -- Dawid Zalewski of the University of Twente, Netherlands, has developed a mini-laboratory on a chip that can purify biological mixtures continuously. This is very different from the usual method that can only process small quantities at a time. In fifteen minutes, the PhD student’s chip processes no less than 25,000 times as much liquid as a ‘normal chip’ in a single cycle. Zalewski was awarded his doctorate on 24 October at the faculty of Science and Technology.

Lab-on-a-chip technology, which involves complete chemical laboratories the size of a chip, is on the rise. Many of these mini-laboratories are able to separate mixtures - of biological substances, for instance. This usually occurs with the aid of capillary electrophoresis; that is, a mixture is led through a thin tube over which a high voltage is applied. The voltage causes the components in the mixture to move through the tube. The size, shape and charge of the molecules affect the speed with which they move. The components that move the fastest are the first to reach the end of the tube and can be collected there - separately from the other molecules.

Dawid Zalewski has developed a new form of capillary electrophoresis that can separate substances continuously: synchronized continuous-flow zone electrophoresis. In a quarter of an hour this method can process around five microlitre of liquid. This does not sound like very much, but a regular capillary electrophoresis chip can only process a couple of hundred picolitre of liquid in a cycle. This tiny quantity is not a problem if, for example, you only want to show whether a certain substance is present in a mixture. But if you want to process the pure substance further, this is a fundamental limitation. Zalewski’s chip is not limited in this way and can process 25,000 times as much liquid as a normal chip in a single cycle, in a quarter of an hour.

No mechanical components

The point of departure in the method developed by Zalewski was that the separation would only take place electrokinetically and that there would be no mechanical components, such as tiny pumps, on the chip. After all, mechanical components break more quickly and, furthermore, pumps are difficult, and therefore expensive, to produce at this scale.

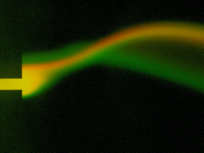

Zalewski’s method uses an additional difference in voltage, perpendicular to the existing electrical field. As a result, the substances are not only separated in the horizontal direction, but also in the vertical direction. Since the additional difference in voltage is not constant but changes in time, the pure substances come out in a wavelike movement. The collector, the part of the chip that collects the pure substance, moves up and down with this wave movement.

Incidentally, the PhD student has already made further modifications to his chip. The improved version has a second collector so that the chip can separate two different pure substances simultaneously.

Provided by Universiteit Twente