Micro-engines

A programme for research on millimetre scale internal combustion engines is being jointly developed by Cambridge Combustion Research Centre and the Centre for Micro-Engineering and Nanotechnology at the University of Birmingham. This micro-engine project brings together novelties in fabrication, combustion, and micro-engine design with a close interaction of micro-fabrication and combustion expertise.

Most liquid hydrocarbon fuels hold over 300 times more energy per unit weight than a NiCad battery and 100 times more than a Li-ion battery. A micro-engine would have the potential to release the energy from the fuels and possibly replace batteries in portable devices.

It would not only last much longer than a battery of the same weight (about 20 times at 10% efficiency), but also requires little time to change its fuel capsule. As a highly compact energy source, micro-engines could find applications in medical devices, military equipment, PDAs, notebook computers, mobile phones, and even toys!

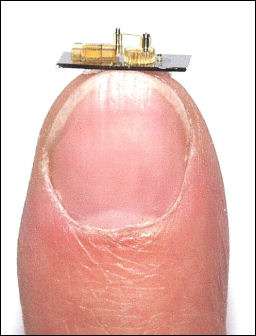

The original idea for making a micro-engine using Micro-Electro-Mechanical Systems (MEMS) technology was proposed by Alan Epstein and Stephen Senturia of Massachusetts Institute of Technology (MIT) in the mid-1990s. Research in Europe started at the University of Birmingham in 1999 and resulted in a patented fabrication process and several prototype micro-engines. The proposed collaboration project between the two Universities intends to produce a micro combustion engine, with platform of 5 x 15 x 3 mm in overall dimension and the expected indicated power output at 11.2 W at a speed of the order of 50,000 rpm.

One of the major problems with the micro-engines is that silicon-based components cannot withstand the high temperatures of combustion. A second barrier is to actually produce sustained combustion in the small dimensions, which are affected by heat transfer. The solution proposed by the investigators is to make micro components out of ceramic materials, and to operate the engine at high speeds using autoignition processes to overcome the heat transfer problem. The investigators are hopeful that the development of the process will allow micro-engines to be brought to the market.

Source: University of Cambridge