New Miniaturized Device for Lab-on-a-Chip Separations

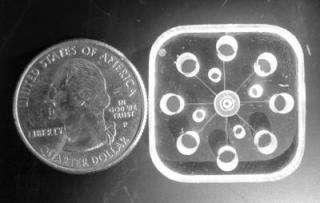

Researchers at the National Institute of Standards and Technology have developed an elegantly simple, miniaturized technique for rapidly separating minute samples of proteins, amino acids and other chemical mixtures. A low-cost prototype device described in a recent paper can run up to eight separations simultaneously in a space about the size of a quarter, highlighting the technique's potential for use in microfluidic "lab-on-a-chip" systems.

Conventional electrophoresis instruments separate mixtures of electrically charged species--DNA fragments, for example--by injecting a discrete sample of the mixture at one end of a chemical race track, such as a capillary tube filled with a buffer solution, and applying a high voltage between the sample and the other end of the track.

Depending on their size, charge and chemical "mobility," the individual components of the mixture move down the track at different rates, gradually separating into individual bands. If two of the components move at very similar rates, it will require a relatively long channel--up to 50 centimeters or longer--to separate them effectively.

The new NIST technique, "gradient elution moving boundary electrophoresis" (GEMBE), works instead by opposing the movement of the mixture's components with a stream of buffering solution flowing at a variable rate. Like salmon swimming upstream, only the most mobile components can move up the channel against the highest buffer flow rates, but as that flow is reduced gradually, lesser mobility components begin to move. A sensor placed over the channel detects each new component as it arrives,

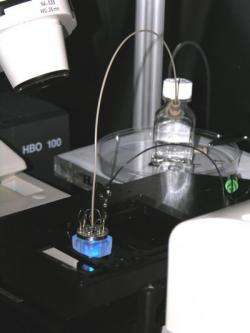

GEMBE is ideally suited for use in microfluidic "lab-on-a-chip" devices. Components are selected by buffer flow-rate rather than distance, so the channel can be very short--less than a centimeter in NIST prototypes. It doesn't require injection of a discrete sample, which greatly simplifies chip plumbing. By precisely controlling the flow rate, a particular component can be "parked" under the detector as long as desired to get a good signal, and the device can be adjusted easily to accommodate different separations. The device is easy to build with simple machining or molding techniques and low-cost polymers, enabling inexpensive mass production.

The technique has been validated at NIST with separations ranging from small dye molecules and amino acids to larger biomolecules, such as DNA. A prototype eight-channel GEMBE device built at NIST can produce a complete immunoassay calibration curve for insulin in a single run. NIST is applying for a patent on the method.

Citation: J.G. Shackman, M.S. Munson and D. Ross. "Gradient elution moving boundary electrophoresis for high-throughput multiplexed microfluidic devices." Anal. Chem., 79 (2), 565 -571, 2007. 10.1021/ac061759h S0003-2700(06)01759-8 on line at pubs.acs.org/cgi-bin/abstract. … 2/abs/ac061759h.html

Source: National Institute of Standards and Technology