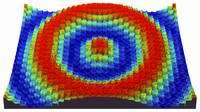

Micromirrors Correct Optical Errors

Before undergoing laser eye surgery, patients are given a glimpse of their future vision through an array of movable miniature mirrors. The technique originated in astronomy, where secondary mirrors in terres-trial telescopes correct distortions caused by the Earth’s atmosphere.