Chemists spray their way to better catalysts

Using a technique called ultrasonic spray pyrolysis, researchers at the University of Illinois at Urbana-Champaign have created an improved catalyst for removing smelly sulfur-containing compounds from gasoline and other fossil fuels. The improved catalyst is a form of molybdenum disulfide, most commonly recognized as the black lubricant used to grease automobiles and machinery.

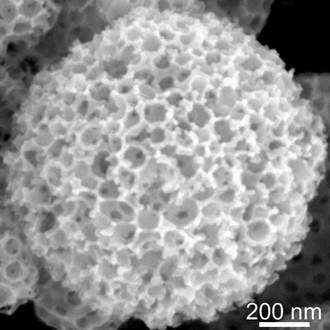

Image: Scanning electron micrograph of molybdenum disulfide produced by ultrasonic spray pyrolysis. Large pores expose catalytically active edge sites.

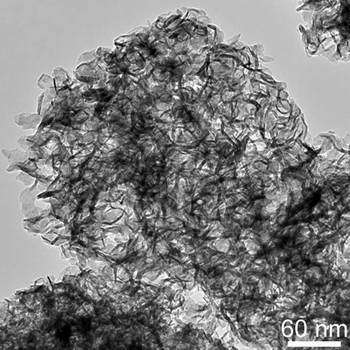

Molybdenum disulfide is made of long flat layers of molybdenum metal atoms sandwiched above and below by single atomic layers of sulfur. The interactions between sulfur-sulfur planes are weak, so they can easily slide past one another, providing excellent high-temperature lubrication.

Molybdenum disulfide's other important commercial application is as a catalyst used by the petroleum industry to remove ecologically damaging sulfur-containing compounds in gasoline. When burned, these sulfur compounds cause the formation of acid rain.

"The flat planes of molybdenum disulfide that make it a good lubricant also decrease its ability to react with fuels to remove sulfur," said Ken Suslick, the Marvin T. Schmidt Professor of Chemistry at Illinois and a researcher at the Beckman Institute for Advanced Science and Technology. "This is because all the reactions necessary for sulfur removal occur on the edges of the long planes, and the bigger the planes, the less relative edge there is."

Using ultrasonic spray pyrolysis, Suslick and graduate student Sara Skrabalak discovered a way to make a highly porous network of molybdenum disulfide that preferentially exposes the catalytic edges. The researchers describe their work in a paper that has been accepted for publication in the Journal of the American Chemical Society, and posted on its Web site. Funding was provided by the National Science Foundation.

Using an ordinary household ultrasonic humidifier, Suslick and Skrabalak spray small droplets of precursor solutions into micron-sized droplets. The droplets are then carried by a gas stream into a furnace, where the solvent evaporates and dissolved substances react to form a product.

This spray-synthesis technique has allowed for the continuous, inexpensive production of spherical powders of varying composition. Research efforts are expanding this technique to the production of nanoparticles and industrially important catalysts.

The new form of molybdenum disulfide is made by spraying droplets of a water solution of ammonium tetrathiomolybdate (a molybdenum disulfide precursor) and colloidal silica (very fine sand). As the droplets are heated in the furnace, water evaporates and a molybdenum disulfide/silica composite is formed. The composite is then treated with hydrofluoric acid, which etches away the silica and leaves a network of molybdenum disulfide behind.

"This treatment leaves pores where the silica used to be and exposes the catalytically active edge of molybdenum disulfide," Suslick said. "Molybdenum disulfide is the standard industrial catalyst for hydrodesulfurization (the removal of sulfur from fuels using hydrogen), but this unique form of molybdenum disulfide has superior catalytic properties when compared to conventionally synthesized molybdenum disulfide."

In addition, the new spray-synthesis route to catalytic materials is simple, easily scaled-up, and can be adapted to other industrial materials.

Source: University of Illinois at Urbana-Champaign