Motorola Debuts First Ever Nano Emissive Flat Screen Display Prototype

Building Upon Carbon Nanotube Technology, Motorola Prepares to Revolutionize the Flat Panel Display Industry

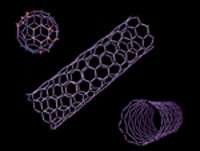

Motorola Labs today unveiled a working 5-inch color video display prototype based on proprietary Carbon Nanotube (CNT) technology – a breakthrough technique that could create large, flat panel displays with superior quality, longer lifetimes and lower costs than current offerings. Optimized for a large screen High Definition Television (HDTV) that is less than 1-inch thick, this first-of-its kind NED 5-inch prototype harnesses the power of CNTs to fundamentally change the design and fabrication of flat panel displays.

The development of such a flat panel display is possible due to Motorola Labs Nano Emissive Display (NED) technology, a scalable method of growing CNTs directly on glass to enable an energy efficient design that excels at emitting electrons. Through this cost-effective process and design, Motorola showcases the potential to create longer-lasting NED flat panel displays with high brightness, excellent uniformity and color purity.

“With over 15 years experience and 160 patents in CNT and flat panel displays, we have developed a technology that could enable the next generation of large size flat panel displays to deliver an extraordinary visual experience at a fraction of current prices,” said Jim O’Connor, vice president, Motorola technology incubation and commercialization. “We now look forward to aligning with display manufacturers and enabling them to further this technology and develop commercially available solutions.”

“Motorola’s NED technology is demonstrating full color video with good response time,” said Barry Young, VP and CFO of DisplaySearch, a leading flat panel display market research and consulting company. “And according to a detailed cost model analysis conducted by our firm, we estimate the manufactured cost for a 40-inch NED panel could be under $400.”

Motorola’s proprietary CNT growth process provides excellent precision in designing and manipulating a material at its molecular level – enhancing specific characteristics – and, in the case of flat panel displays, producing high-definition images. The electron emission performance demonstrated by the Motorola technology exceeds that achieved to date with the application of the CNT to the cathode via an organic paste, the process used by other companies.

“Motorola has proven its NED technology to be fully video capable,” said Kimberly Allen, Director Display Technology and Strategy for analyst firm iSuppli. “CNT direct growth on glass appears to have advantages over CNT paste/printing approaches and has potential for larger and more sophisticated displays.”

Motorola’s industry-first working prototype demonstrates:

• Operational full color 5" video section of a 1280 x 720, 16:9, 42-inch HDTV

• High quality brightness

• Bright, vivid colors using standard Cathode Ray Tube (CRT) TV phosphors

• Display panel thickness of 3.3 millimeters (about 1/8th of an inch)

• Low cost display drive electronics (similar to LCD, much lower than Plasma)

• Display characteristics meet or exceed CRTs, such as fast response time, wide

viewing angle, wide operation temperature