Printing of components with functional ink

Time is money - even in component manufacturing. Researchers can continuously print out three-dimensional metal parts using a rapid manufacturing process. The unique feature is that they can vary the material composition in many ways.

Practice makes perfect, but even an expert in tool engineering and mold construction may be at his wits' end sometimes. If the craftsman is to integrate special features such as hard surfaces into parts with a complex shape, he would be well advised to use a generative process instead of machining. Rapid manufacturing processes of this kind do not remove material, but instead build up the pieces layer by layer.

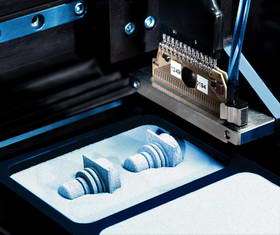

Image: This metal printer has built up storage battery terminals layer by layer. © Fraunhofer IFAM

One example is the metal printer. First of all, the machine lays down a thin layer of powdered steel on a base plate. A binder material is sprayed onto it in the desired shape by the printhead, and cured with a heat lamp.

Then the printer starts on the next layer, which typically has a thickness of 0.1 millimeters. In this way the workpiece gradually gains height, and when the process is complete you have a component made of binder and steel powder that is already the right shape. In the next step, the part is sintered at just below melting point: The binder disintegrates and the powder grains fuse together, leaving a component with a density of up to 98 percent. The shrinkage which takes place at the same time can easily be counterbalanced by making the part a defined amount larger to begin with.

By using binder materials containing sub-micrometer particles, researchers from the Fraunhofer Institute for Manufacturing Engineering and Applied Materials Research IFAM in Bremen are now able to integrate additional functions in the components. "We have developed together with ProMetal the process to a stage where we can produce controlled local variations in the composition of the components," project manager Ingo Wirth is pleased to report. "The 3D gradient printing method with 'functional ink' opens up completely new horizons for this sector of industry."

As an example: tooling inserts or embossing dies for sheet metal must not be too brittle, and should preferably therefore only be hard on the surface. Inside, however, they should be tough but softer. The IFAM researchers were able to solve this problem without a separate hardening stage by using a second printhead. This applies a mixture of binder and finely distributed carbon powder only at certain points within the layers. When the part is subsequently post-sintered to its full density, the steel will only be harder in those specific places. The possibilities are boundless. In principle, it is possible to construct parts made of pure metal A on one side and pure metal B on the other. Various alloys can be placed in between.

Source: Fraunhofer-Gesellschaft