December 20, 2014 weblog

Off-world manufacturing is a go with space printer

On Friday, the BBC reported on a NASA email exchange with a space station which involved astronauts on the International Space Station using their 3-D printer to make a wrench from instructions sent up in the e-mail. Quite a marker for things to come? An object, after all, was designed on Earth and then transmitted to space for manufacture, indicating such events may have an impact on the economics of supply and demand for space missions. Astronauts would be more self-reliant on future long-duration space missions if on-demand manufacturing were in place, as an alternative to launching the actual items from Earth. NASA in this recent episode was responding to a request by ISS commander Barry Wilmore for a ratcheting socket wrench. Previously, said the BBC, if astronauts requested a specific item they could have waited months for it to be flown up on one of the regular supply flights. The BBC posed the question, "If a 3D printer can churn out something as useful as a tool in space, what else is possible?" The sky is no longer the limit. "Spare parts, components, even equipment, according to the company behind the printer, Made In Space. And that's just the start."

Made In Space had overheard ISS Commander Barry Wilmore mention over the radio that he needed one [wrench], "so we designed one in CAD and sent it up to him faster than a rocket ever could have," said Mike Chen, Made in Space chief strategy officer and co-founder, writing in the Backchannel website.

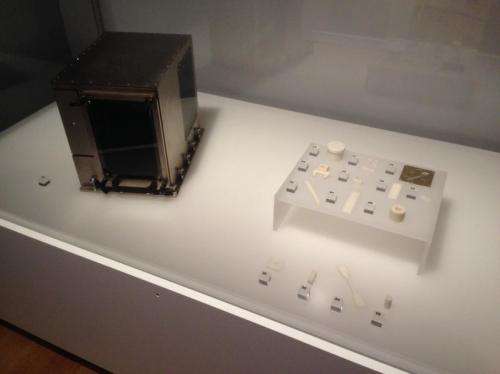

Made In Space's expertise with regard to 3D printing in zero-gravity led to the first 3D printers designed for use on the International Space Station. The Zero-G Printer was designed to operate in zero gravity, launched into orbit in September; the printer was built under a joint partnership between NASA MSFC and Made In Space.

Made In Space's additive manufacturing technology creates 3D objects layer by layer from filament through an extrusion method specifically adapted for the space environment. They designed the part in CAD, and converted it into a format ready for the 3D printer. They sent it to NASA from their office, using a combination of in-house and NASA software. NASA sent it to the space station, by way of a support center, linking developers and researchers on the ground with their payloads on the ISS.

"Looking further ahead, the thinking becomes even more radical," said the BBC. Made In Space said it's been trying out possible raw materials for its printers including a substance similar to lunar soil. "So in theory, a 3D printer dispatched to the Moon might be able to dig into the lunar surface, scoop up what is called the regolith, and transform it into the elements needed for a moon base," said the BBC.

In November, reported Wired.co.uk, astronauts aboard the ISS printed a replacement part for the recently installed 3D printer. A total of 21 objects have been printed in space, to be returned to Earth for testing. (The other 20 objects, wrote Chen in Backchannel, were designed before the printer flew to the space station.) Chen will welcome the learning experience. He said that they will be compared to identical objects manufactured on the ground. "We will use them to characterize the effects of long-term microgravity on our 3D-printing process, so that we can model and predict the performance of objects that we manufacture in space in the future," said Chen in Backchannel.

Chen believes it makes far more sense for a 3d printer in space. "Because it's a lot faster to send digital data (which can travel at the speed of light) to space than it is to send physical objects (which involves waiting months to years for a rocket), it makes more sense to 3D-print things in space, when we can, instead of launching them."

Chen added, "When we do set up the first human colonies on the moon, Mars and beyond, we won't use rockets to bring along everything we need. We'll build what we need there, when we need it."

More information: www.madeinspace.us/front-blog

© 2014 Tech Xplore