July 22, 2014 weblog

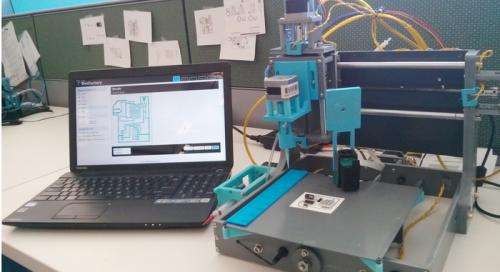

Squink personal factory aims to make circuit prototyping easy

The team at BotFactory have launched a Kickstarter campaign for their prize endeavor, Squink, to bring it to life. The team behind Squink started out with the question, what if making circuit boards were easy? This is a personal electronic circuit factory, and "its purpose is to make circuit prototyping as easy and seamless as possible." A promotional video showing Squink makes that clear. Put another way, this is a personal factory for electronic circuits, which sits on your desk, and, in minutes, prints and assembles your circuits on flexible or rigid substrates. Think of the device, though, not as a printer but as a something more. The Squink uses conductive ink to print traces from Gerber files or any other image file and assembles your circuit. The Squink takes this further step than just printing out the designs that connect the components on a circuit board; it is designed also to pick and place those components onto the board, as per the design on the computer. As TechCrunch explained, "The printer applies conductive glue dots onto the ink and then picks up components from a tray, aligns them and places them on the glue dots."

The creators explained: "You can access your Squink through USB, Ethernet cable, or Wifi. After you create or download circuit design files (GERBER), upload them to Squink and it will walk you through a three step process. You can also use regular PNG files if you feel artistic!"

Circuit boards are used in all electronic devices—from cell phones to computers. The advantage here is being able to create plug and play circuit boards, said 3DPrint.com, in about 30 minutes. Andrew Liszewski in Gizmodo:summed up what is special about their device, as it "lets hobbyists and aspiring Wozniaks print their own functional circuit boards using conductive ink and glue, for almost immediate turnarounds when they make revisions to a design."

The origins of Squink are with a group of engineers who met at NYU Polytechnic School of Engineering. They worked on a proof of concept during a prototyping competition at the school, sharing a common goal to solve an electronic boards problem—as the physical brains of electronic devices, the boards are everywhere but the problem is they are hard to make. Large manufacturers are geared to high volume and home fabrication is messy, they said. What is more, it is expensive to make flexible boards or use different materials. The 3D printers were "pushing mechanical design to new heights," they said, "but there was nothing out there for electrical design." They wrote that "The final prototype used a syringe to lay down conductive ink and needed a lot of programming for every circuit made. But it worked."After that initial success, they expanded the team and worked to improve speed and precision "by orders of magnitude," they said.

This "personal electronic circuit factory".device is being offered at $2,999 with an estimated delivery date of April 2015. There are also higher-priced options. Gizmodo noted that "being able to churn out a revised circuit board in just half an hour might make a lot of financial sense in the long run." At the time of this writing the team had gathered pledges totaling $38,637 with a $100,000 goal and 29 days left.

More information: www.kickstarter.com/projects/b … onic-circuit-factory

© 2014 Tech Xplore