March 13, 2014 report

Researchers develop new kind of internal combustion microengine

(Phys.org) —A team of researchers with members from Russia, The Netherlands and Germany has developed a new kind of microengine, based on the possible combustion of oxygen and hydrogen. In their paper published in Scientific Reports, the team describes how they built the new engine, how they think it works, and what it could mean for the development of future microsystems.

As scientists have built ever smaller devices, the need for ever smaller microengines has grown, unfortunately, the science for tiny engines hasn't kept pace. Those based on electrostatic forces aren't able to produce enough power and traditional combustion engines become less and less efficient as they are made smaller. In this new effort, the researchers built a tiny combustion engine in a new way that overcomes the problems of others before it, though they can't say for sure how it works.

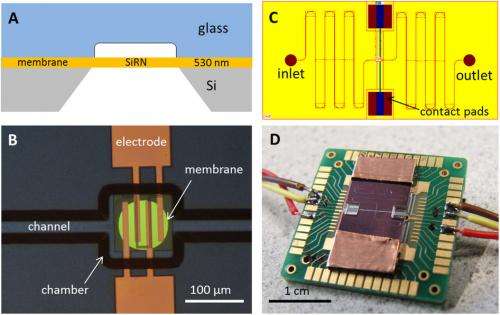

The engine is very simple. The team built a tiny pressure chamber with a flexible membrane at one end, they then added wires inside that ran through a saltwater solution. Sending current through the wires caused hydrogen and oxygen in the water to disassociate into tiny bubbles (i.e. electrolysis). That caused an increase in pressure inside the chamber (approximately 3.6 bar) forcing the membrane to bend outwards (approximately 1.4 microns). Turning off the current caused the membrane to return to its natural shape, but oddly, it did so much faster than it should have due to dissipation—the researchers suspect that instead the gas was combusted back into water molecules. In any event, quickly cycling back and forth a membrane can be used as a force mechanism—an engine.

Remarkably, the new microengine is just 100×100×5 microns in size and was fabricated using silicon wafers covered with a layer of silicon rich nitride and platinum electrodes. The membrane was part of the wafer, etched from the back side.

The microengine produces a lot of torque for its size, and thus could very well serve as the basis for very tiny devices that need to either perform physical work (e.g. pump fluid), or move around (perhaps inside human blood vessels). At the same time, it's a certainty that the original team and others will set to work trying to nail down exactly why the engine works and to determine just how small such an engine could be.

More information: New type of microengine using internal combustion of hydrogen and oxygen, Scientific Reports 4, Article number: 4296 DOI: 10.1038/srep04296

Abstract

Microsystems become part of everyday life but their application is restricted by lack of strong and fast motors (actuators) converting energy into motion. For example, widespread internal combustion engines cannot be scaled down because combustion reactions are quenched in a small space. Here we present an actuator with the dimensions 100 × 100 × 5 μm3 that is using internal combustion of hydrogen and oxygen as part of its working cycle. Water electrolysis driven by short voltage pulses creates an extra pressure of 0.5–4 bar for a time of 100–400 μs in a chamber closed by a flexible membrane. When the pulses are switched off this pressure is released even faster allowing production of mechanical work in short cycles. We provide arguments that this unexpectedly fast pressure decrease is due to spontaneous combustion of the gases in the chamber. This actuator is the first step to truly microscopic combustion engines.

© 2014 Phys.org