Bone replacement from laser melting

(PhysOrg.com) -- In a medical emergency, a puncture of the cranium is commonly treated with an implant. While replacements made of titanium merely plug holes, a new kind of degradable implant stimulates the body to regenerate itself: It is custom-fit and disappears to the same extent that the bone regrows.

The body can heal minor bone injuries itself - but with major injuries, it needs help. That‘s when implants frequently come into use. In contrast to long-term solutions based on titanium, degradable implants are intended to replace the missing pieces of bone only until the fissure closes itself up. That may last months or even years, depending on the size of the defect, the age and health status of the patient. A new implant improves the conditions for the healing process.

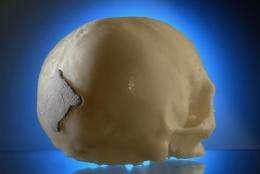

It emerged from the "Resobone" project of the federal ministry for education and research, and is sized-to-fit for each patient. Unlike the conventional bony substitutes to date, it is not made up as a solid mass, but is porous instead. Precise little channels permeate the implant at intervals of just a few hundred micrometers. "Its precision fit and perfect porous structure, combined with the new biomaterial, promise a total bone reconstruction that was hitherto impossible to achieve," as Dr. Ralf Smeets of the University Medical Center of Aachen summarizes the findings of the first tolerability studies.

The porous canals create a lattice structure which the adjacent bones can grow into. Its basic structure consists of the synthetic polylactide, or PLA for short. The stored granules from tricalcium phosphate (TCP) ensure rigidity and stimulate the bone‘s natural healing process. As pastes, granulates and semi-finished products, TCP and PLA already have proven to be degradable implants. The body can catabolize both substances as rapidly as the natural bones can regrow. But the material can only be applied in places where it will not be subject to severe stress: Thus, the "Resobone" implants will primarily replace missing facial, maxillary and cranial bones. Currently, they are able to close fissures of up to 25 square centimeters in size. Their unique structure is made possible through a manufacturing process that was developed at the Fraunhofer Institute for Laser Technology ILT in Aachen, Germany, for the development of industrial prototypes - Selective Laser Melting (SLM): A razor-thin laser beam melts the pulverized material layer-by-layer to structures that may be as delicate as 80 to 100 micrometers.

The patient‘s computer tomography serves as the template for the precision-fit production of the implants. The work processes - from CT imaging, to construction of the implant, through to its completion - are coordinated in such precise sequences that the replacement for a defective zygomatic bone can be produced in just a few hours, while a five-centimeter large section of cranium can be done overnight. In addition to the obvious benefits, there is a considerable gain in time during surgery: "No custom-fit, degradable implants ever existed before now. During the operation, the surgeon had to cut TCP cubes, or the patient‘s own previously removed bone material, to size and insert it into the fissure," explains Simon Höges, Project Manager at ILT. In addition, the operations are now fewer in number: Physicians no longer take the bone replacement from the patient‘s own pelvic bone.

Similarly, they can dispense with the countless follow-up operations on children to exchange long-term implants that don‘t grow as the child matures. "We have achieved our project goal: a closed process chain to produce individual bony implants from degradable materials," explains Höges with satisfaction. Now it is up to the project partners - which also include implant manufacturers - who must turn the results into products.