Material scientists have found a way to enhance implant protection

The TSU materials scientists with the Research and Production Enterprise have developed a reliable system for protecting the surface of titanium nickelide products, in particular, implants. Having studied the mechanisms of corrosion resistance of alloys, scientists first discovered metal-ceramic particles and the oxycarbonitride layer, which provide high chemical compatibility of the surface and protect the material from biological fluids exposure. Now, by adjusting the conditions for creating alloys, materials scientists will be able to change the corrosion resistance of implants.

Today the study of how porous alloys develop their corrosion resistance is the most difficult task on the verge of the capabilities of modern devices.

- For the first time, we at TSU showed the phase composition of a dense, corrosion-resistant surface layer of porous titanium nickelide, which provides reliable protection against the corrosive effects of biological fluids of a living organism,- says Yury Yasenchuk, senior researcher at the TSU Scientific Research Institute . - The protective layer is formed in the process of creating a porous alloy without additional coatings and surface treatments. Our studies allowed us to identify the mechanism of its formation and understand how to improve it.

Scientists note that, depending on the goals, it will be possible to create implants with different levels of biocompatibility. Improving the anti-corrosion properties of titanium nickelide alloys will allow materials scientists, with doctors, to successfully solve the problems of bone plastics in various areas of surgery. Now under the grant of the Russian Science Foundation, scientists are developing methods for the formation of protective coatings on implants obtained by other technological methods.

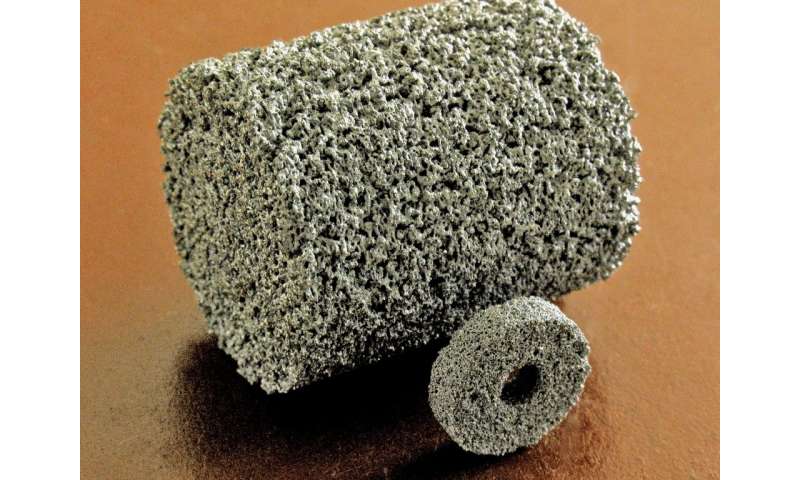

Porous nickelide titanium with shape memory effect and superelasticity in its biomechanical properties is similar to human bone tissue. Thanks to the spongy morphology, it is used to replace bone defects in various diseases. Biomechanical compatibility allows it to easily integrate into the bones of a living organism and function in it for a long time. The most important aspect of the biocompatibility of implants is the corrosion resistance of their surface. However, the nature of this resistance was not previously explained due to the complexity of direct access to the pore surface of the material.

Provided by Tomsk State University