This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Predicting the composition of a steel alloy

Producing energy on Earth through nuclear fusion, the type of reaction that powers the sun, has proven to be a major challenge. The extreme conditions needed for such a reaction require the walls of a nuclear fusion device to be made of a material with a particular set of mechanical properties, including being able to withstand incredibly high temperatures and be shock- and corrosion-resistant. Austenitic steel, a non-magnetic steel with a crystalline structure, is one of the materials considered for use in nuclear fusion devices.

In a new paper in The European Physical Journal D, Ivan Traparić and Milivoje Ivković from the Institute of Physics in Belgrade, Serbia, explore an effective way to predict the composition of austenitic steel.

They found that laser-induced breakdown spectroscopy—a technique to determine the quantity of elements in a material—used in combination with a deep neural network—a machine learning technique—was most effective. This technique could be used to determine the elemental composition of a steel sample by those without access to certified steel samples.

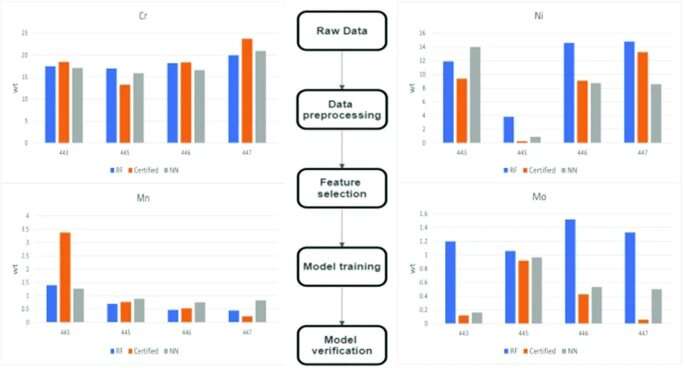

The researchers used machine learning techniques in combination with laser-induced breakdown spectroscopy to speed up the process of identifying the elements that compose austenitic steel samples. They used a criterion called the Gini impurity test to select the most important data from their dataset, enabling them to minimize its complexity. They then used this simplified dataset to train their machine learning models to identify the composition of their steel samples.

The authors conclude that, when used in combination with laser-induced breakdown spectroscopy, a neural network was better at predicting the composition of austenitic steel than random forest, a machine learning technique that employs a collection of decision trees.

More information: Ivan Traparić et al, Determination of austenitic steel alloys composition using laser-induced breakdown spectroscopy (LIBS) and machine learning algorithms, The European Physical Journal D (2023). DOI: 10.1140/epjd/s10053-023-00608-6

Journal information: European Physical Journal D

Provided by Springer