This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Pulsed discharge plasma helps in heavy oil conversion

The increasingly inferior quality of heavy oil resources has brought more difficult challenges to traditional heavy oil processing technology. The high temperature and pressure conditions, and the carbon emission and energy consumption required to convert heavy oil to value-added chemicals are far from ideal.

Plasma technology is a potential approach to tackle this problem without catalysts, high-temperature and high-pressure conditions during the reaction. It also has advantages of short process flow, low carbon emissions and wide material adaptability. However, this technology is complicated due to the inert nature of heavy oil.

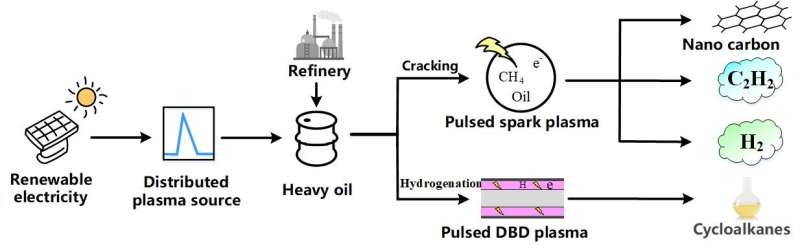

Researchers led by Prof. Shao Tao from the Institute of Electrical Engineering (IEE) of the Chinese Academy of Sciences (CAS) and their collaborators have explored the conversion laws and reaction mechanisms of plasma-enabled heavy oil conversion using different types of pulsed discharge plasma, and converted heavy oil into acetylene, carbon materials or cycloalkanes.

Their research findings have been published in the Chemical Engineering Journal with the titles "Catalyst-free toluene hydrogenation to methyl-cyclohexane by pulsed DBD plasma under ambient conditions" and "One-step high-value conversion of heavy oil into H2, C2H2 and carbon nanomaterials by non-thermal plasma."

With microsecond pulsed spark discharge plasma, the researchers investigated heavy oil cracking characteristics in terms of pulse voltage, pulse repetition frequency and discharge power. Emission spectral analysis revealed the rapid heating and cooling mechanism of the pulsed spark plasma.

They achieved one-step cracking of heavy oil into acetylene, hydrogen and nano-carbon materials, with heavy oil conversion rate of 50.4%, acetylene yield of 19.7%, and energy consumption of 55.4 kWh/m3.

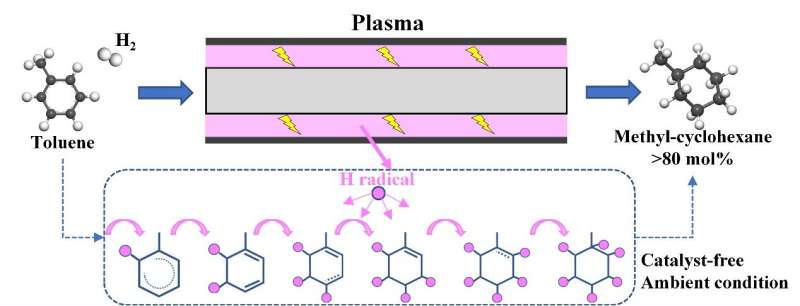

Moreover, using pulsed dielectric barrier discharge plasma, the researchers realized non-catalytic aromatics hydrogenation to cycloalkanes at mild conditions, which has broken the limitation of catalysts and harsh conditions in conventional heavy oil processing.

Isotope conversion experiment and density functional theory calculation revealed the mechanism and kinetic process of hydrogen radical hydrogenation, which has laid a foundation for the study of plasma mass oil hydrogenation process.

More information: Hao Sun et al, Catalyst-free toluene hydrogenation to methyl-cyclohexane by pulsed DBD plasma under ambient conditions, Chemical Engineering Journal (2023). DOI: 10.1016/j.cej.2023.142823

Zhe Fan et al, One-step high-value conversion of heavy oil into H2, C2H2 and carbon nanomaterials by non-thermal plasma, Chemical Engineering Journal (2023). DOI: 10.1016/j.cej.2023.141860

Provided by Chinese Academy of Sciences