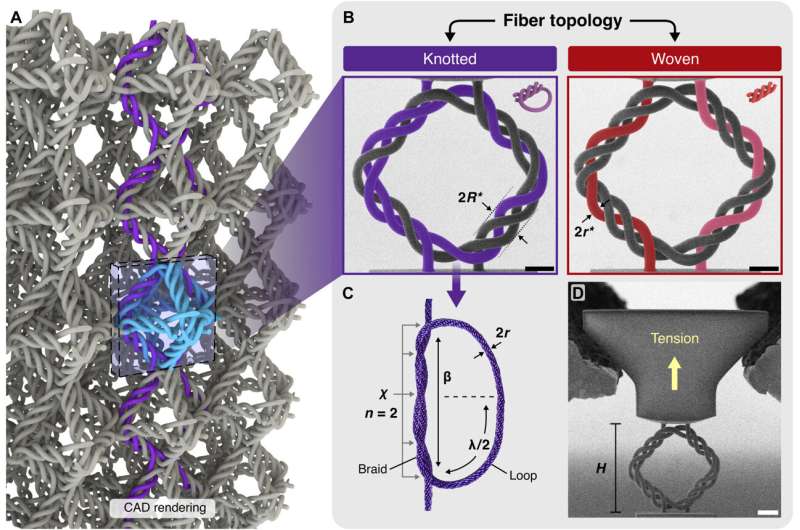

Knotted and woven fiber topologies in hierarchical intertwined materials. (A) Computer-aided design (CAD) rendering of a hierarchical octahedron lattice where each unit cell is composed of three rhombuses. The rhombus in the rectangular box is formed by two knotted fibers, one being highlighted in purple and tessellated vertically. (B) SEM images with color shading overlaid onto a single fiber in the knotted (left) and woven (right) hierarchical rhombuses, each with two vertically connected fibers. An overhand knot is formed by each of the two fibers (one colored purple and the other uncolored) in the knotted rhombus. Vertical fibers in the woven rhombus are colored red and pink, respectively. (C) Photograph of an overhand knot that resembles the purple knot in (A). (D) An in situ experimental setup inside an SEM on a representative intertwined rhombus frame. Scale bars, 10 μm (B) and 20 μm (D). Credit: Science Advances (2023). DOI: 10.1126/sciadv.ade6725

In the latest advance in nano- and micro-architected materials, engineers at Caltech have developed a new material made from numerous interconnected microscale knots.

The knots make the material far tougher than identically structured but unknotted materials: they absorb more energy and are able to deform more while still being able to return to their original shape undamaged. These new knotted materials may find applications in biomedicine as well as in aerospace applications due to their durability, possible biocompatibility, and extreme deformability.

"The capability to overcome the general trade-off between material deformability and tensile toughness [the ability to be stretched without breaking] offers new ways to design devices that are extremely flexible, durable, and can operate in extreme conditions," says former Caltech graduate student Widianto P. Moestopo, now at Lawrence Livermore National Laboratory. Moestopo is the lead author of a paper on the nanoscale knots that was published on March 8 in Science Advances.

Moestopo helped develop the material in the lab of Julia R. Greer, the Ruben F. and Donna Mettler Professor of Materials Science, Mechanics and Medical Engineering; Fletcher Jones Foundation director of the Kavli Nanoscience Institute; and senior author of the paper. Greer is at the forefront of the creation of such nano-architected materials, or materials whose structure is designed and organized at a nanometer scale and that consequently exhibit unusual, often surprising properties.

The tensile strength of a material constructed with microscale knots (left), compared to that of a material that lacks knots but is otherwise structurally identical (right). Credit: Caltech

"Embarking on understanding how the knots would affect the mechanical response of micro-architected materials was a new out-of-the-box idea," Greer says. "We had done extensive research on studying the mechanical deformation of many other types of micro-textiles, for example, lattices and woven materials. Venturing into the world of knots allowed us to gain deeper insights into the role of friction and energy dissipation, and proved to be meaningful."

Each knot is around 70 micrometers in height and width, and each fiber has a radius of around 1.7 micrometers (around one-hundredth the radius of a human hair). While these are not the smallest knots ever made—in 2017 chemists tied a knot made from an individual strand of atoms—this does represent the first time that a material composed of numerous knots at this scale has ever been created. Further, it demonstrates the potential value of including these nanoscale knots in a material—for example, for suturing or tethering in biomedicine.

The knotted materials, which were created out of polymers, exhibit a tensile toughness that far surpasses materials that are unknotted but otherwise structurally identical, including ones where individual strands are interwoven instead of knotted. When compared to their unknotted counterparts, the knotted materials absorb 92 percent more energy and require more than twice the amount of strain to snap when pulled.

The knots were not tied but rather manufactured in a knotted state by using advanced high-resolution 3D lithography capable of producing structures in the nanoscale. The samples detailed in the Science Advancespaper contain simple knots—an overhand knot with an extra twist that provides additional friction to absorb additional energy while the material is stretched. In the future, the team plans to explore materials constructed from more complex knots.

Moestopo's interest in knots grew out of research he was conducting in 2020 during the COVID-19 lockdowns. "I came across some works from researchers who are studying the mechanics of physical knots as opposed to knots in a purely mathematical sense. I do not consider myself a climber, a sailor, or a mathematician, but I have tied knots throughout my life, so I thought it was worth trying to insert knots into my designs," he says.

The paper has a tongue-in-cheek title—"Knots are Not for Naught: Design, Properties, and Topology of Hierarchical Intertwined Microarchitected Materials."Naval Research.

More information: Widianto P. Moestopo et al, Knots are not for naught: Design, properties, and topology of hierarchical intertwined microarchitected materials, Science Advances (2023). DOI: 10.1126/sciadv.ade6725

Journal information: Science Advances

Provided by California Institute of Technology