This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Shape memory achieved for nano-sized objects

Alloys that can return to their original structure after being deformed have a so-called shape memory. This phenomenon and the resulting forces are used in many mechanical actuating systems, for example in generators or hydraulic pumps. However, it has not been possible to use this shape-memory effect at a small nanoscale. Objects made of shape-memory alloy can only change back to their original shape if they are larger than around 50 nanometers.

Researchers led by Salvador Pané, Professor of Materials of Robotics at ETH Zurich, and Xiang-Zhong Chen, a senior scientist in his group, were able to circumvent this limitation using ceramic materials. In a study published in the journal Nature Communications, they demonstrate the shape-memory effect on a layer that is about twenty nanometers thick and made of materials called ferroic oxides. This achievement now makes it possible to apply the shape-memory effect to tiny nanoscale machines.

A special structure is needed

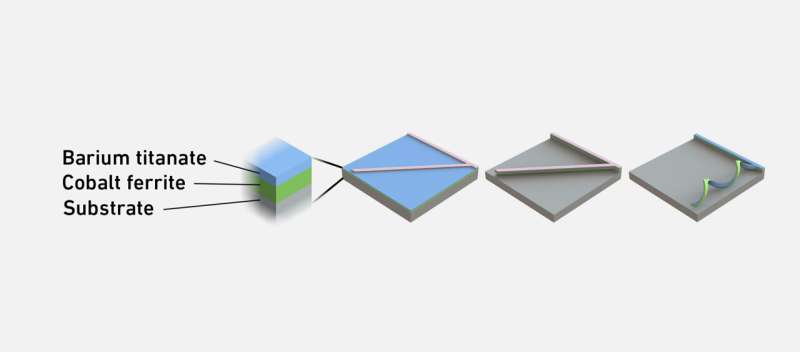

At first glance, ferroic oxides do not appear to be very suitable for the shape-memory effect: They are brittle in bulk scale, and in order to produce very thin layers of them, they usually have to be fixed onto a substrate, which makes them inflexible. In order to still be able to induce the shape-memory effect, the researchers used two different oxides, barium titanate and cobalt ferrite, of which they temporarily applied thin layers onto a magnesium oxide substrate. The lattice parameters of the two oxides differ significantly from each other. After the researchers had detached the two-layered strip from the supporting substrate, the tension between the two oxides generated a spiral-shaped twisted structure.

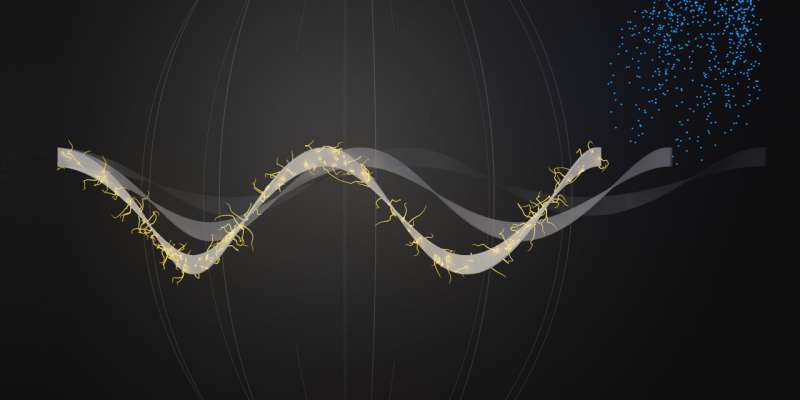

Such free-standing nanoscale structures made of ferroic oxides are highly elastic, resilient, and they allow flexible movements. Furthermore, they showed a shape-memory effect: When the researchers applied mechanical tensile force to the structure, it stretched out and permanently deformed. Subsequently, the scientists directed an electron beam from a scanning electron microscope onto the deformed structure; it returned to its original shape. The electrical energy thus triggered a shape-memory effect. The layer thickness of about twenty nanometers is the smallest sample size on which such an effect has ever been observed.

Usually, in other examples, the shape-memory effect is triggered by thermal or magnetic manipulation. "The reason it works with electrical irradiation in ferroic oxides may have to do with the orientation of the polarization within the oxides, we suspect," says Chen. While the free-standing structure is being stretched, the polarization within the oxides aligns parallel to the structure plane. The electron beam, however, leads the polarization to align perpendicular to the structure plane, causing change of the mechanical strain and contract to its original shape.

Broad range of applications

This response to the electrical energy is more suitable for wide range of applications, because punctual temperature manipulations (conventionally used to induce shape memory) are not possible at the nanoscale. One example of an application: Thanks to their high elasticity, the oxides could replace muscle fibers or parts of the spine.

"Other applications would be new nanoscale robotic systems: The mechanical movement that occurs when switching between the two structures could be used to drive tiny motors," says Donghoon Kim. He worked as a doctoral student on this study and is one of its two lead authors. "Furthermore, our approach could also facilitate the development of longer-lasting small-scale machines, because the material is not only elastic but also durable," says Minsoo Kim, postdoc and also a lead author.

The range of applications can even be extended to flexible electronics and soft robotic systems. In another study, which the researchers have just published in the journal Advanced Materials Technologies, they were able to further develop such free standing oxide structures so that their magnetoelectric properties can be controlled and tuned more precisely. Such shape memory oxides could be used, among other things, to manufacture nanorobots that are implanted in the body and can stimulate cells or repair tissue. Through external magnetic fields, the the nanorobots can be triggered to transform into a different shape and perform specific functions within a human body.

"Furthermore, the magnetoelectric properties of these shape-memory oxide structures could be used, among other things, to electrically stimulate cells within the body, for example to activate neuronal cells in brains, for cardiac therapies, or for accelerating bone healing process," Pané says. Finally, the magnetoelectric shape-memory oxides could be used in nanoscale devices, such as tiny antennas or sensors.

More information: Donghoon Kim et al, Shape-memory effect in twisted ferroic nanocomposites, Nature Communications (2023). DOI: 10.1038/s41467-023-36274-w

Minsoo Kim et al, Strain‐Sensitive Flexible Magnetoelectric Ceramic Nanocomposites, Advanced Materials Technologies (2023). DOI: 10.1002/admt.202202097

Journal information: Advanced Materials Technologies , Nature Communications

Provided by ETH Zurich