March 16, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

A cheaper and more flexible alternative to indium tin oxide

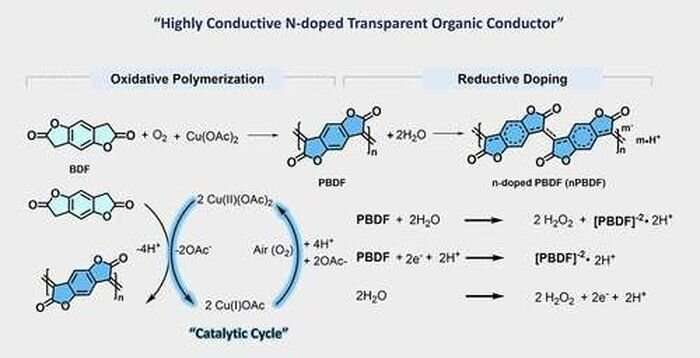

A team of chemists at Purdue University, working with a pair of colleagues from the University of Kentucky, has developed a way to make PBDF, a type of transparent conducting material, at an easily synthesized scale. In their paper published in Journal of the American Chemical Society, the group describes their new technique and possible applications.

Touch screens, such as those used on smartphones and tablet computers, are able to convey finger commands via a layer of electrically conductive film made of indium tin oxide (ITO). Such films are expensive to make, tend to be rigid and require the use of indium, a post-transition metal that can be toxic if consumed.

Since the introduction of its use in personal electronic devices, scientists have been looking for a substitute. One promising organic material is PBDF—it is stable in natural conditions and more electrically conductive than other organic clear conductors. It also can be printed onto surfaces, and bent and twisted without suffering damage. Its one main drawback has been the inability to synthesize it at scale and at a reasonable cost. In this new effort, the research team working in Indiana has found a way around this problem.

The researchers developed a new synthetic technique for creating PBDF using water and air to initiate bonds, along with a copper-based catalyst. Other techniques have relied on nitrogen gas instead of air. That is what makes the new technique so much easier to scale.

The research team demonstrated the creation of a thin film using their technique by spraying it onto a surface. Testing showed that the film allowed 80% of light to pass through, which is similar to ITO. They also found it remained stable over 20 days of exposure to temperature changes, from −20 to 65 °C.

The group plans to push ahead with their work—their goal is to make the thin films more conductive by eliminating small defects that occur during application. They also plan to modify the material to make it more conducive to use as ink for printing applications.

More information: Zhifan Ke et al, Highly Conductive and Solution-Processable n-Doped Transparent Organic Conductor, Journal of the American Chemical Society (2023). DOI: 10.1021/jacs.2c13051

Journal information: Journal of the American Chemical Society

© 2023 Science X Network