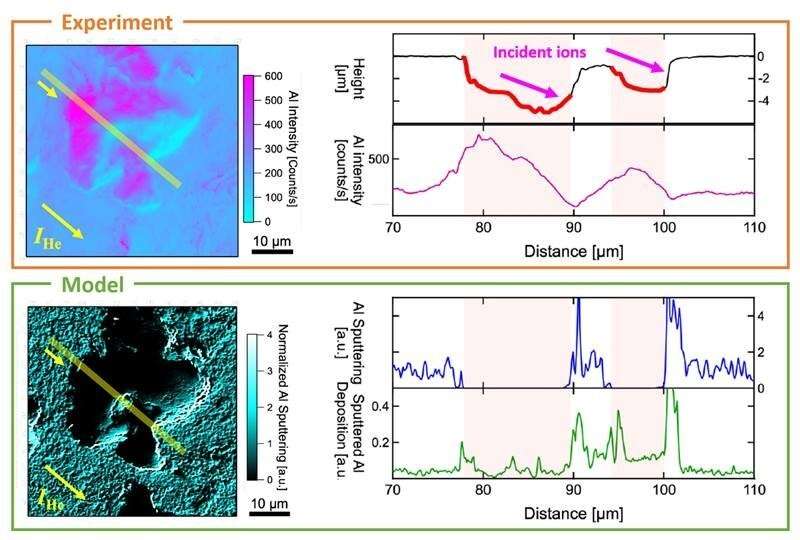

Surface maps and line scans (represented by yellow lines) of topology and aluminum (Al) composition on a rough carbon sample (experiment at top vs. model at bottom). Regions shadowed from incoming helium (He) ions (yellow and magenta arrows) are shaded. Credit: Physics of Plasmas (2022). DOI: 10.1063/5.0095155

As plasma circulates in a fusion device, the surface of the device that faces the plasma erodes. This releases particles of surface material. Most erosion occurs through a process called sputtering, where a particle strikes a surface and results in the ejection of atoms from that surface. The number of atoms eroded for each incident particle, known as the sputtering yield, varies depending on the angle at which the incident particle contacts the surface.

In a fusion device, the trajectory of the incident particle does not necessarily change over time. However, processes such as erosion, deposition, and melting of the wall result in localized changes to the angle at which the particle bombards the surface. Most models used to estimate erosion of the plasma-facing wall assume that the smoothness of the surface does not change with time. To test this assumption, scientists studied laboratory-scale plasma devices to examine the relationship between surface roughness and erosion.

Designing, building, and installing a plasma-facing wall with low erosion and minimal surface damage is critical for future fusion power reactors. As the plasma-facing surface erodes away, the surface releases unwanted impurities into the plasma. This compromises the device's performance and reduces the lifespan of its components. Scientists rely on empirical models to predict the rate of erosion in fusion devices. These models are based on real-world observations rather than mathematical descriptions.

Now, new research builds on previous studies to examine the erosion behavior of rough surfaces in a tokamak. Its goal is to more accurately approximate a realistic fusion environment. The research aims to revise existing models to account for the dramatic changes in sputtering yield caused by continuous roughening of the plasma-facing surface.

Erosion and deposition of the plasma-facing wall are expected to change throughout the reactor lifetime as the surface undergoes various types of mechanical and thermal damage. Researchers at the DIII-D National Fusion Facility, a Department of Energy (DOE) user facility, used erosion measurements from graphite and silicon carbide samples with varying degrees of roughness taken during a recent experiment to develop an empirical model that estimates erosion based on surface topology.

The paper is published in the journal Physics of Plasmas.The team included scientists from Princeton University, Princeton Plasma Physics Laboratory, University of Illinois at Urbana-Champaign, San Diego State University, and General Atomics.

The researchers used three-dimensional measurements of surface topology and composition taken before and after exposure in DIII-D to provide key inputs to a sputtering simulation code that was used to estimate the rates of erosion and deposition, as well as the fraction of the surface shadowed from incident particles. They attributed a reduction in the sputtering yield from rough surfaces of up to 50% to local changes to the angle at which incoming particles strike the surface. On average, they calculated the sputtering yield for a rough surface was at 75% of that for a smooth surface.

By quantifying the relationship between the surface topology and the sputtering yield of the material using computer modeling, scientists will be able to more accurately predict the erosion of rough surfaces, which are expected to evolve significantly throughout the lifetime of a fusion device.

More information: S. Abe et al, Computational investigation of incident ion angles and material erosion at rough graphite and silicon carbide divertor surfaces, Physics of Plasmas (2022). DOI: 10.1063/5.0095155

Journal information: Physics of Plasmas

Provided by US Department of Energy