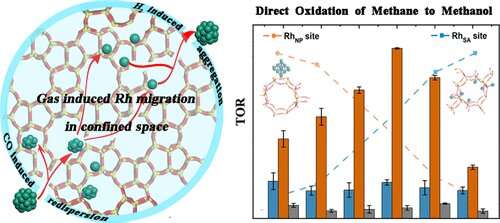

Graphical abstract. Credit: ACS Catalysis (2023). DOI: 10.1021/acscatal.2c05463

The migration of Rh atoms under a gas/reactive environment is important for the dynamic restructuring and size redistribution of Rh catalysts in a variety of structure-sensitive catalytic reactions.

Recently, a research group led by Prof. Zhang Tao and Assoc. Prof. Yang Bing from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. Zhou Si from the Dalian University of Technology, revealed a controlled-release mechanism to regulate Rh atom migration through two-dimensional (2D) zeolite nanosheets (ZSM-5-2D).

This study was published in ACS Catalysis on Jan. 5.

"The migration rate of Rh atoms can be precisely controlled by regulating the mutual interaction of the gas environment and support confinement, enabling a quasi-continuous size control over a wide range from single atom to nanoparticle reversibly," said Yang.

Through a variety of state-of-the-art in-situ characterizations, the researchers directly observed the dynamic aggregation/redispersion of Rh catalysts in/out of the ZSM-5-2D, enabling a quasi-continuous size control over a wide size range from Rh single atom to Rh nanoparticle reversibly.

The catalytic testing for mild oxidation of methane disclosed that the sub-nanometer Rh nanoclusters accounted for the highest methanol activity of 39.7 molCH3OOH·molRh-1·h-1 with a remarkable selectivity as high as 73.2%, far beyond that of single atom species and larger particles.

Density functional theory calculations and electron paramagnetic resonance spectroscopy further elucidated the size dependency by examining the formation of ·OH radicals for methane oxidation.

"This work reveals a controlled-release mechanism in zeolite-encaged Rh catalyst, which is inspiring for the design of atomically precise catalysts," said Yang.

More information: Hong Li et al, Controlled-Release Mechanism Regulates Rhodium Migration and Size Redistribution Boosting Catalytic Methane Conversion, ACS Catalysis (2023). DOI: 10.1021/acscatal.2c05463

Journal information: ACS Catalysis

Provided by Chinese Academy of Sciences