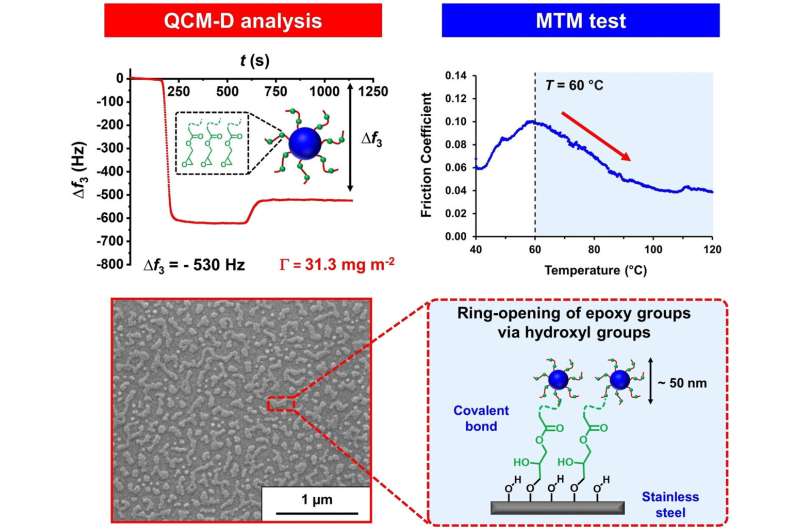

Graphical Abstract. Introduction of epoxy groups into sterically-stabilized diblock copolymer nanoparticles leads to their efficient chemical adsorption onto stainless steel whereas the corresponding non-functional nanoparticles merely undergo physical adsorption. Significantly greater adsorption occurs when the epoxy groups are placed within the steric stabilizer chains, which leads to enhanced lubrication in tribology studies. Credit: Angewandte Chemie International Edition (2023). DOI: 10.1002/anie.202218397

Mineral oil lubricants protect engine parts from wear, and this effect is enhanced by adding polymer nanoparticles to the lubricating oil. A UK team has now discovered that epoxy functionalization of these nanoparticles further promotes friction reduction on metal surfaces.

As the team reports in the journal Angewandte Chemie, nanoparticles containing epoxy groups adhere strongly to stainless steel surfaces, which leads to a significant reduction in friction.

Automotive engines comprising well lubricated parts consume less fuel, produce lower emissions, and suffer less long-term wear. Mineral oil is widely used as a lubricant, and nanoparticles can be directly prepared within this solvent using a technique known as polymerization-induced self-assembly. Coating the surface of the metal components with nanoparticles of a few dozen millionths of a millimeter in size protects them from direct contact.

Csilla György and Steve Armes at the University of Sheffield (UK) designed "hairy" nanoparticles comprising oil-soluble poly(lauryl methacrylate) chains and an oil-insoluble nanoparticulate core. These nanoparticles were made to stick strongly to metal surfaces by introducing epoxy groups into the "hairs" by copolymerizing lauryl methacrylate with glycidyl methacrylate, an epoxy-functional monomer.

The team found that the epoxy-bearing nanoparticles reacted with hydroxy groups located at the surface of stainless steel. This reaction led to strong adhesion of the nanoparticles, a phenomenon known as chemical adsorption. Whether chemical adsorption occurred or not depended on the precise location of the epoxy groups. "To our surprise, introducing a far larger number of epoxy groups into the nanoparticle cores had no beneficial effect," explains Armes.

The adsorbed nanoparticles reduced friction significantly, as the Sheffield team discovered when conducting tribological studies in collaboration with scientists at Lubrizol, an engine oil additives company based in the UK. "Remarkably, the adsorbed nanoparticles remained intact on the stainless steel surface after such experiments, which were conducted at the typical operating temperature of an internal combustion engine," Armes adds.

Such epoxy-functionalized nanoparticles could therefore mean a further leap in performance for lubricant additives for next-generation engine oil formulations.

More information: Csilla György et al, Enhanced Adsorption of Epoxy‐Functional Nanoparticles onto Stainless Steel Significantly Reduces Friction in Tribological Studies, Angewandte Chemie International Edition (2023). DOI: 10.1002/anie.202218397

Journal information: Angewandte Chemie International Edition , Angewandte Chemie

Provided by Angewandte Chemie