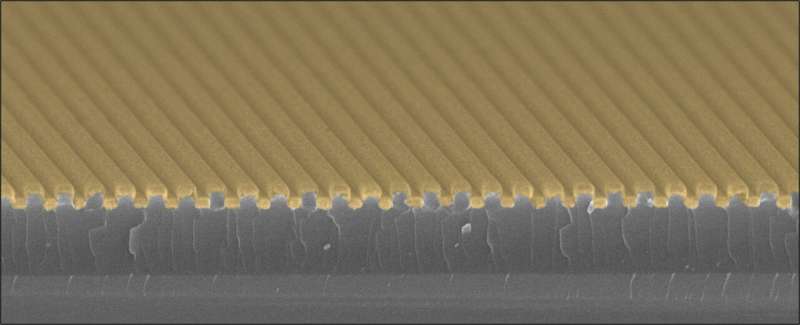

Sulfur-rich polymer-based infrared polarizer. Credit: W. Cho, et al., Adv. Mater, 2022, 2209377

Polarimetric images can provide information such as shading and surface morphologies by using polarizers that selectively reflect the transverse electric (TE) field and transmit the transverse magnetic (TM) field of unpolarized incident light. However, current IR polarizers are mainly based on expensive and brittle ceramics (such as semiconductors and chalcogenides) with nano-gratings usually fabricated by time- and cost-consuming interference lithography.

Recently, a sulfur-rich polymer, synthesized by "inverse-vulcanization," has received much attention as a suitable candidate for IR optics, owing to its intrinsic high transmittance in the IR region. The sulfur-rich polymer is mainly composed of an elemental sulfur-based backbone. Notably, there are 7 million tons of sulfur created annually as a surplus from petroleum-refining processes. Hence, this sulfur-rich polymer can be mass-produced with high economic feasibility.

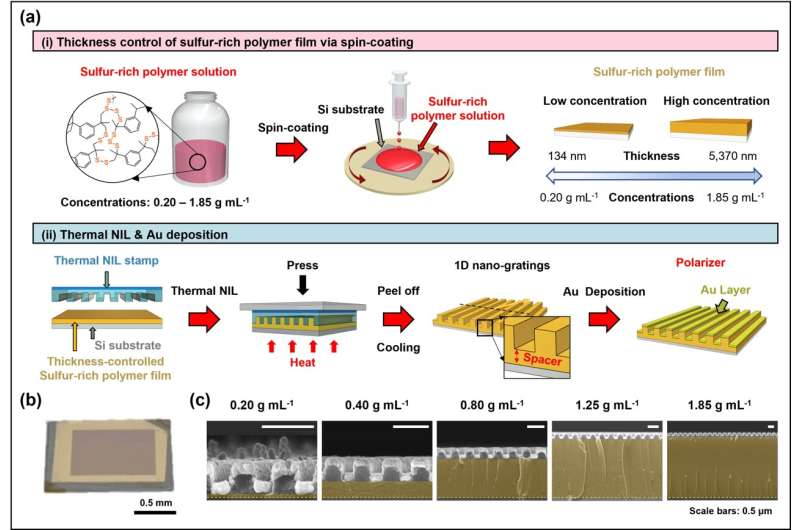

Unlike conventional IR materials, the sulfur-rich polymer can be solubilized in an organic solvent which means a solution-based process, represented as spin-coating, can be applied. In addition, the viscoelasticity and dynamic covalent disulfide bonds allow the sulfur-rich polymer to be molded to diverse nanostructures by thermal-based processing represented as thermal nanoimprinting lithography (thermal NIL).

As a structure of sulfur-rich polymer-based polarizer, the bilayer structure is feasible and can be obtained by the following 3-steps; (1) spin-coating a sulfur-rich polymer solution, (2) thermal NIL onto a spin-coated sulfur-rich polymer-based film, and (3) metal deposition on the nano-gratings. The sulfur-rich polymer-based polarizer is comprised of a self-aligned bilayer metallic grating (upper and lower Au layers) and a spacer layer (applied as the optical cavity).

For highly sensitive polarizers, it is required to have both a high TM transmission and extinction ratio (ER; the ratio of TM transmission to TE transmission) for a broadband IR region. During thermal NIL, it is difficult to replicate high-quality nano-gratings of the nano-scale master mold by using the viscoelastic sulfur-rich polymer, due to the high surface tension originating from a high surface-area-to-volume ratio of the master mold.

Low-quality thermal NIL causes low-fidelity nano-gratings that have round and wavy-shaped gratings, inducing the connection of upper and lower metal layers after metal deposition and deteriorating polarizer sensitivity. In addition, it is hard to maximize polarizer sensitivity by satisfying the Febry-Pérot resonance indicating conditions for maximum TM transmission, without tailoring the spacer thickness applied as an optical cavity. When the incident light passes through the bilayer structured polarizer, multiple reflections occur in the spacer layer in the role of the optical cavity. The Febry-Pérot resonance is a condition where reflected lights are in-phase and make constructive interference.

(a) Schematic illustration of preparing Sulfur-rich polymer-based infrared polarizer (i) spin-coating process of sulfur-rich polymer solution (ii) thermal nanoimprinting lithography (thermal NIL) and the following Au deposition. (b) Digital image of the sulfur-rich polymer-based polarizer. (c) Spacer thickness-controlled sulfur-rich polymer-based polarizers as a function of concentrations of the sulfur-rich polymer solution. Credit: W. Cho, et al., Adv. Mater, 2022, 2209377

Led by Jeong Jae (JJ) Wie, Associate Professor at the Department of Organic and Nano Engineering at Hanyang University, researchers finally achieved a highly sensitive sulfur-rich polymer-based polarizer. For this, the research team fine-tuned the thermal NIL conditions to replicate designed nano-gratings with high-quality and investigated the spacer thickness to maximize TM transmission for all MWIR regions.

Published in Advanced Materials, the research team successfully demonstrated a sulfur-rich polymer-based IR polarizer with a pitch of 400 nm designed by numerical simulations with considerations to optical performance and fabrication difficulty. The high-fidelity 1D nano-grating was obtained over an area of 1 × 1 cm2 by systematic investigation of thermal NIL conditions including temperature, pressure, and time, taking into account the relationship between time and pressure explained by Stefan's squeeze flow equation and thermal behavior of sulfur-rich polymers such as glass transition and thermal degradation.

An unprecedented milestone in the field, the thickness of sulfur-rich polymer spacer was tunable over a wide range from 40 nm to 5,100 nm, as a function of the concentration of sulfur-rich polymer solution. As a result, the optical performance of sulfur-rich polymer-based polarizer corresponded to TM transmissions of 0.65, 0.59, and 0.43 and ERs of 3.12 × 103, 5.19 × 103, and 5.81 × 103 at 4 μm for spacer thicknesses of 90, 338, and 572 nm, respectively. In particular, the ER of 5.81 × 103 at MWIR is a world record among reported sulfur-rich polymer-based polarizers (19.1 times higher than that of previously reported polymeric sulfur-based polarizers).

More information: Woongbi Cho et al, Highly Sensitive and Cost‐Effective Polymeric‐Sulfur‐Based Mid‐Wavelength Infrared Linear Polarizers with Tailored Fabry–Pérot Resonance, Advanced Materials (2022). DOI: 10.1002/adma.202209377

Journal information: Advanced Materials

Provided by Hanyang University