New approach extracts more data on steel alloys for materials databases

A new approach uses data from one type of test on small metal alloy samples to extract enough information for building databases that can be used to predict the properties and potentials of new materials. The details were published in the journal Science and Technology of Advanced Materials: Methods.

The test is called instrumented indentation. It involves driving an indenter tip into a material to probe some of its properties, such as hardness and elastic stiffness. Scientists have been using the data extracted from instrumented indentation to estimate the stress-strain curve of materials using computational simulations.

This curve, and the data it provides, is important for understanding a material's properties. That data is also used for building massive materials databases, which can be used, in conjunction with artificial intelligence, for predicting new materials.

A problem scientists face is that this approach for estimating material properties is limited when it comes to materials called "high work-hardening alloys": metal alloys, like steel, that are strengthened through physical processes like rolling and forging. Only so much information can be estimated from the curve of these materials. To get the necessary additional information needed to determine their properties, more experiments would need to be done, which costs time, effort and money.

Ta-Te Chen of the University of Tsukuba and Ikumu Watanabe of the National Institute for Materials Science in Japan have developed a new computational approach to extract that additional information from instrumented indentation tests on work-hardening alloys.

"Our approach builds on an already-existing model, making it ready for use in industry. It is also applicable to existing data, including hardness," says Watanabe.

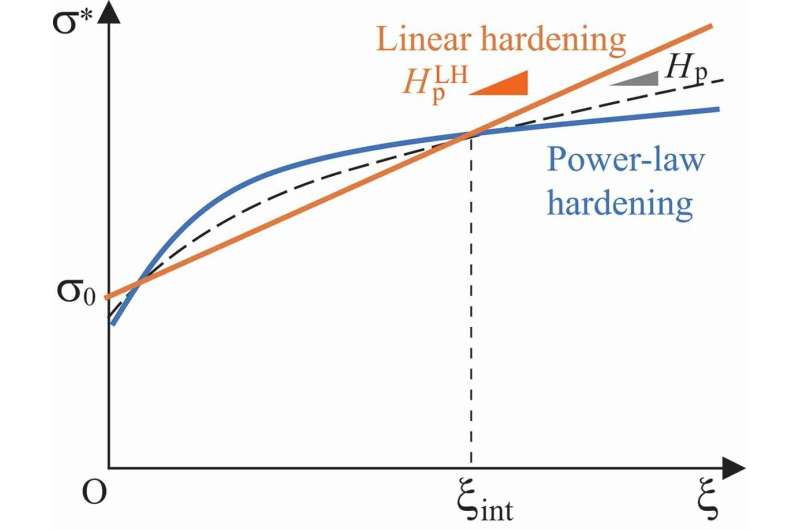

The approach involves combining the results from two computational models, the power-law and linear hardening models, which produce their own individual stress-plastic strain curves from information gathered from indentation tests. Combining the data from both curves provides the extra data that, when added to the original stress-strain curve, shows a more holistic picture of the work-hardening alloys' properties.

The scientists validated their approach by using it on a high-work-hardening stainless steel.

"We have extended this approach to also evaluate mechanical properties at elevated temperatures, which can contribute to the development of high-temperature alloys," says Chen.

More information: Ta-Te Chen et al, Data-driven estimation of plastic properties in work-hardening model combining power-law and linear hardening using instrumented indentation test, Science and Technology of Advanced Materials: Methods (2022). DOI: 10.1080/27660400.2022.2129508

Provided by National Institute for Materials Science