A robust and portable fluorescence microscope has been developed for on-site asbestos detection. Magnification (approximately x300) can be digitally increased (until x1000). Credit: Akio Kuroda

Asbestos is a toxic substance that is found in older buildings, as well as in cosmetics and products for children. As testing for its presence can be problematic, Hiroshima University Professor Akio Kuroda has been working on a novel solution.

Asbestos is a naturally occurring silicate (silicon- and oxygen-containing) mineral that has a fibrous structure. These fibers are composed of microscopic fibers that can become airborne when the asbestos is disturbed, making asbestos easily inhaled. Formerly enjoying widespread use, especially in construction, for its insulation and fireproofing qualities, asbestos has since been banned in many countries. This is due to the discovery, in the 1970s, that asbestos fiber inhalation can cause lung cancer, asbestosis, and other lethal lung conditions.

Professor Akio Kuroda, from the Graduate School of Integrated Sciences for Life at Hiroshima University, is an expert in the field.

"While asbestos has been banned in most developed countries, large quantities of asbestos-containing materials remain in old buildings, and people are at risk of exposure to asbestos during demolition," he explains.

Kuroda confirms that it is not just building materials that pose a risk.

"In addition, natural minerals, such as talc, a raw material used in the manufacture of cosmetics, pharmaceuticals, and baby powder, may also contain asbestos. It has recently been highlighted that asbestos-contaminated talc may cause cancer," he says.

Kuroda is keen to focus on the importance of fast and accurate asbestos testing. In January 2022, the US Food and Drug Administration (FDA) released a report written by the Interagency Working Group on Asbestos in Consumer Products outlining an improved scientific assessment of asbestos in order to better protect the public.

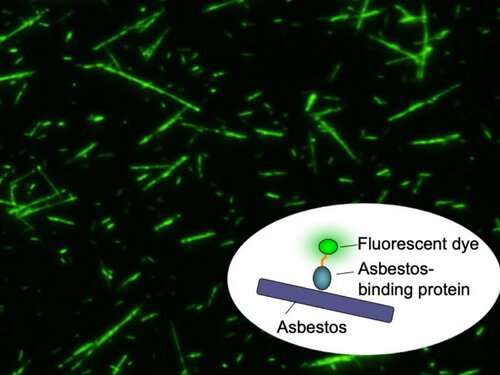

Kuroda and his team have been developing testing techniques to accurately pinpoint the presence of asbestos. Their approach to establishing better testing for asbestos has been twofold, firstly with the development of a fluorescent microscopy (FM) method that offers increased sensitivity as well as convenience, as well as the creation of an asbestos-specific protein probe combined with a fluorescent marker that allows users to easily visualize asbestos fibers, but not non-asbestos ones, under a fluorescent microscope.

A need for improved testing

Testing for asbestos is currently often accomplished using polarized light microscopy (PLM). While this method is convenient and cheap to run, the sensitivity is insufficient for the detection of fine fibers. The FDA recommends transmission electron microscopy (TEM) due to its higher sensitivity. However, it is labor-intensive, and therefore testing becomes more costly.

Other popular testing methods include phase contrast microscopy (PCM) and scanning electron microscopy (SEM). All of these have significant drawbacks that keep the search for a better option going. Kuroda's method using FM offers much higher sensitivity that comes close to rivaling that of electron microscopy, and it is also far more convenient for users than TEM.

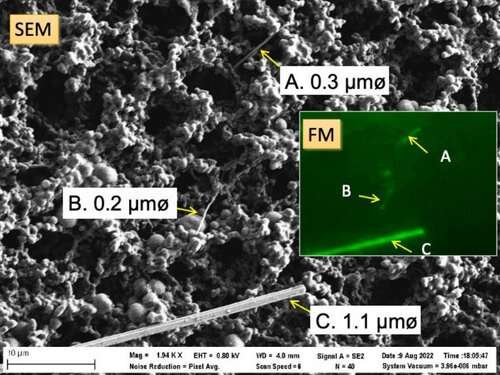

Fine asbestos fibers (A, B, and C) are visible under fluorescent microscopy (FM) and scanning electron microscopy (SEM). Credit: Akio Kuroda

A US National Institutes of Health (NIH) study published in 2012 found that FM was able to detect fibers that were almost ten times smaller than those found by PCM testing, making it a much more sensitive testing method, approaching the accuracy of even electron microscopy. The study concluded that FM demonstrated exciting potential to offer a more accurate option for identifying asbestos fibers without the need for time-consuming, labor-intensive laboratory testing.

Developing a faster, more accurate, and convenient way to test for the presence of asbestos fibers is vital as testing is often required quickly due to the toxic nature of the substance.

Many incidents arise when potential asbestos is released into the air during construction or repair works on older buildings, requiring a speedy result to allow steps to be taken quickly to neutralize the contamination. Thus, SEM and TEM have their drawbacks in these situations, although they do provide reliable, accurate readings.

Despite their provision of clear, accurate results, both generally require samples to be sent to a laboratory to be processed. PCM, on the other hand, can be carried out in situ, enabling faster results. However, this method, in turn, has drawbacks. PCM identifies the presence of airborne fibers but is not able to distinguish between asbestos and other types of fibers.

Overcoming obstacles

Asbestos detection is an area that certainly has room for improvement in finding a method that meets the need for both speed and accuracy. Kuroda believed that existing methods of testing failed to cover these requirements.

"I needed to show evidence that the new technology can be used for asbestos detection," he says.

His approach has been to target FM as a highly specific way to identify asbestos. The most difficult challenge he faced, having developed a specific probe for asbestos, has been to quantify what percentage of fluorescent fibers made visible in the test samples are asbestos.

"To verify the identity of the fibers that were fluorescently tagged, we analyzed them under an electron microscope to identify their elemental composition," Kuroda outlines.

"However, it was very difficult to find the individual fibers under both microscopes in order to verify them."

In a sample that may contain thousands, or even hundreds of thousands of fibers, this task was like finding the proverbial needle in a haystack. Fortunately, Kuroda was able to turn to recent advances in imaging technology to solve this issue.

The fluorescently labeled asbestos-binding proteins visualize asbestos fibers. Credit: Akio Kuroda

"We were able to use a newly developed correlative microscopy system where the sample stage is shared among the two microscopes," he explains.

This means that the location information of fibers therefore remained. Kuroda says the results were astounding.

"We demonstrated that over 95 percent of fluorescent fibers observed in the practical samples are really asbestos," he confirms.

Changing the landscape

Kuroda's work on developing and modifying the asbestos-binding protein with fluorescent dye has been truly groundbreaking. By creating this probe that is highly specific for asbestos, it is now possible to visualize this lethal substance in samples of construction materials, cosmetics and even baby products.

"Before this finding, no one knew that asbestos could be fluorescently visualized," points out Kuroda.

With results published in the Annals of Occupational Hygiene, Kuroda's methods were approved in the Asbestos Monitoring Manual, a guide published by Japan's Ministry of the Environment. The probes he developed in this study have been made commercially available and are currently used by several companies for fast and accurate monitoring of asbestos.

In addition to developing the probe and validating his results, Kuroda has also worked with a commercial manufacturer of microscopes to create a fluorescent microscope that was suitable for use in situ. Existing fluorescent microscopes were unwieldy devices that needed to be used in a laboratory setting and were quite unsuitable for transport around dusty demolition sites.

Aware of the desire for faster testing, Kuroda and his industry partners were able to design a robust and portable microscope that could be taken on-site, thus making testing faster and more accurate.

By tackling multiple problems that had beset the arena of asbestos testing and control, Kuroda has revolutionized the industry, bringing faster, more accurate testing to contaminated sites worldwide. In the UK, where the use of asbestos has been banned since the late 1990s, it is still present in many buildings, with almost 50 percent of buildings, including over 75 percent of schools affected.

In terms of the benefits, this means greater safety not just for construction workers laboring on potentially hazardous sites, but also for all citizens (including children) living and working in polluted homes and buildings. Kuroda's advances in better testing and better equipment mean greater safety for all.

Provided by Hiroshima University