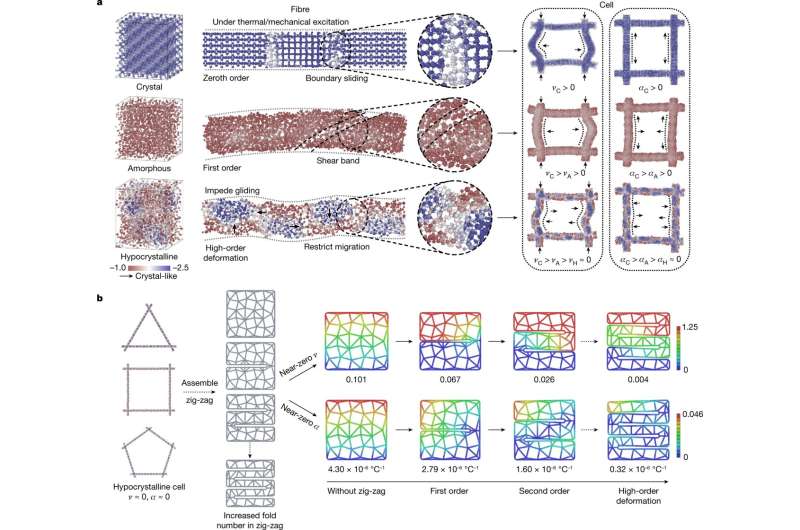

Multiscale design of hypocrystalline ceramic nanofibrous aerogel. a, Deformation modes and the corresponding ν and α of crystalline (C), amorphous (A) and hypocrystalline (H) ceramic fibrous cells under mechanical and thermal excitations. The colored scale bar indicates the variation of ceramics from amorphous to crystal by using a local-entropy-based fingerprint to characterize the crystallinity of each atom in the simulated system. b, Illustration of the zig-zag architecture design based on hypocrystalline fibrous ceramics. The units of the colored scale bars are millimeters, presenting absolute displacement values in ν and α calculation. The triangle, square and pentagon cells are the building units to assemble the fibrous aerogel structure. Credit: Nature (2022). DOI: 10.1038/s41586-022-04784-0

A team of researchers at the Harbin Institute of Technology, in China, working with a colleague in the U.S., has developed a new kind of aerogel for use in flexible thermal insulation material applications. In their paper published in the journal Nature, the group describes how they made their aerogel and how well it worked when extreme heat was applied.

Prior work has shown that aerogels made using ceramic materials work very well as thermal insulators—their very low densities have very low thermal conductivity. But such materials are brittle, making them unavailable for use in flexible material applications, such as suits for firefighters. They also tend to break down when exposed to very high temperatures. In this new effort, the researchers have developed a method for making a ceramic based aerogel that can be used in flexible applications and also does not break down when exposed to very high temperatures.

To create their aerogel, the researchers took a novel approach—they pushed a zirconium-silicon precursor, using a plastic syringe, into a chamber with turbulent airflow—an electrospinning approach that produced a ceramic material that resembled cotton candy. They then folded the resulting material into a zig-zag pattern and heated it to 1100° C. Heating it in such a way changed the texture of the material from a glassy state to a nanocrystal. Study of the resulting material using a spectroscope showed that their approach had resulted in the creation of a material with nanocrystalline bits embedded in an amorphous zircon matrix—a flexible aerogel made using a ceramic that was not prone to breaking down under high temperatures.

The researchers tested the material by using it to insulate an airplane fuel tube and applying a butane blowtorch for five minutes. They found that using a generic polyimide barrier allowed the temperatures in the tube to reach 267° C, while a conventional aerogel kept the temperature to 159° C and the new gel maintained it at just 33° C. They also found that the material was flexible enough to allow for use in flexible cloths, such as those used to make protective clothing for firefighters.

More information: Jingran Guo et al, Hypocrystalline ceramic aerogels for thermal insulation at extreme conditions, Nature (2022). DOI: 10.1038/s41586-022-04784-0

Journal information: Nature

© 2022 Science X Network