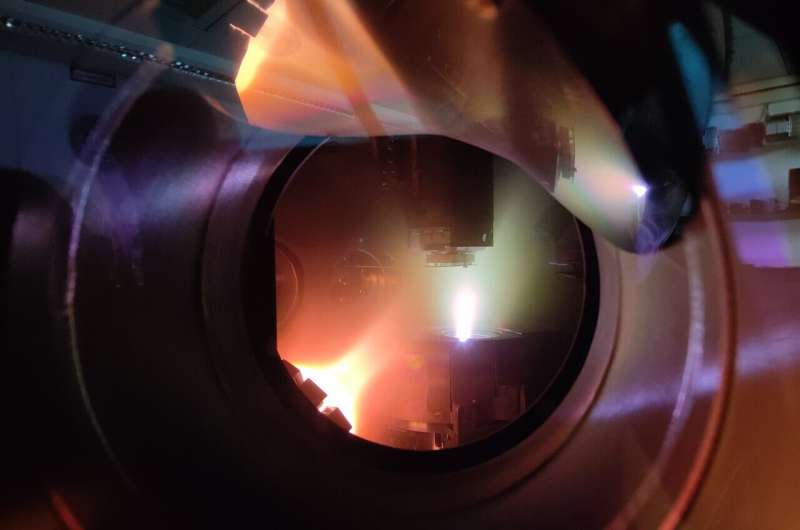

Pulsed laser deposition: An intense laser pulse hits a target containing the material, tranforming it into a plasma which is then deposited as a thin film onto a substrate. Credit: R. Gottesman/HZB

Producing low-cost metal-oxide thin films with high electronic quality for solar water splitting is not an easy task. Especially since quality improvements of the upper metal oxide thin films need thermal processing at high temperatures, which would melt the underlying glass substrate. Now, a team at HZB-Institute for Solar Fuels has solved this dilemma: A high intensity and rapid light pulse directly heats the semiconducting metal-oxide thin film, allowing to achieve the optimal heating conditions without damaging the substrate.

Solar energy can directly drive electrochemical reactions at the surface of photoelectrodes. Photoelectrodes consist of semiconducting thin films on transparent conductive-glass substrates that convert light into electricity. Most photoelectrochemical studies have focused on water splitting, a thermodynamically uphill reaction that could offer an attractive pathway for the long-term capture and storage of solar energy by producing "green" hydrogen.

Metal-oxide thin film photoelectrodes are particularly interesting for these diverse functions. They comprise abundant elements, potentially offering infinite tunability to achieve the desired properties—at potentially low costs.

Made from plasma

At the HZB Institute for Solar Fuels, several teams focus on developing such photoelectrodes. The usual method to produce them is pulsed laser deposition: an intense laser pulse hits a target containing the material and ablates it into a highly energetic plasma deposited on a substrate.

Quality needs heat

Further steps are needed to improve the quality of the deposited thin film. In particular thermal processing of the metal-oxide thin-film reduces defects and imperfections. However, this creates a dilemma: Reducing atomic defects concentration and improvements in crystalline order of the metal-oxide thin films would require thermal processing temperatures between 850 and 1000 degrees Celsius—but the glass substrate melts already at 550 degrees Celsius.

Flash-heating the thin film

Dr. Ronen Gottesman from the HZB Institute for Solar Fuels has now solved this problem: After deposition, using high-powered lamps, he flash-heats the metal-oxide thin film. This heats it up to 850 degrees Celsius without melting the underlying glass substrate.

"The heat efficiently reduces structural defects, trap states, grain boundaries, and phase impurities, which would become more challenging to mitigate with an increasing number of elements in the metal-oxides. Therefore, new innovative synthesis approaches are essential. We have now demonstrated this on photoelectrodes made of Ta2O5, TiO2, and WO3, which we heated to 850 °C without damaging the substrates," says Gottesman.

Record performance for α-SnWO4

The new method was also successful with a photoelectrode material that is considered a very good candidate for solar water splitting: α-SnWO4. Conventional furnace heating leaves behind phase impurities. Rapid thermal processing (RTP) heating improved crystallinity, electronic properties, and performance, leading to a new record performance of 1 mA/cm2 for this material, higher by 25% than the previous record.

"This is also interesting for the production of quantum dots or halide perovskites, which are also temperature-sensitive," explains Gottesman.

The research was published in ACS Energy Letters.

More information: Ronen Gottesman et al, Shining a Hot Light on Emerging Photoabsorber Materials: The Power of Rapid Radiative Heating in Developing Oxide Thin-Film Photoelectrodes, ACS Energy Letters (2022). DOI: 10.1021/acsenergylett.1c02220

Provided by Helmholtz Association of German Research Centres