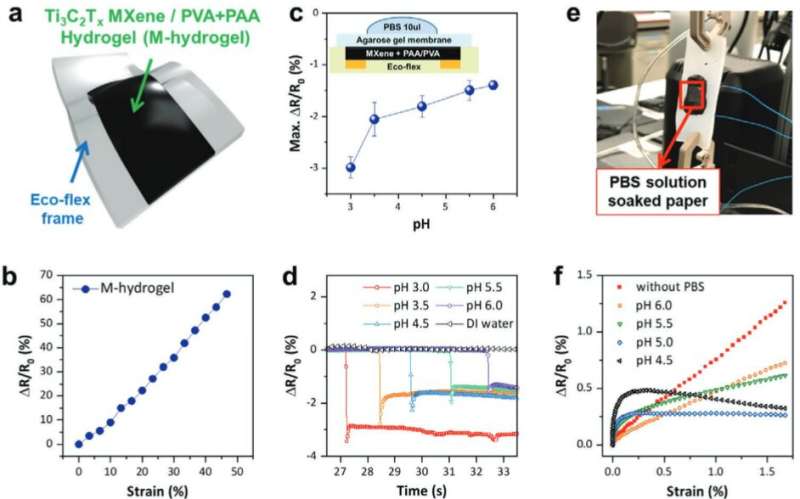

Figure1. a) Schematic showing the design of the muscle fatigue sensor based on Ti3C2Tx MXene-PVA/PAA hydrogel (M-hydrogel). b) Effect of applied axial strain on the resistance of the M-hydrogel (ΔR/R0). c) Variation of the electrical resistance of the M-hydrogel with pH; the pH was controlled by changing the composition of the PBS solution. d) Time-dependent change in the resistance of the M-hydrogel as a function of pH of the environment. Sudden changes in M-hydrogel resistance are observed upon dropping in PBS solutions having different pH values. e) Photo image showing the experimental setup to measure the resistance of the M-hydrogel under applied strain at different pH conditions. f ) Nonlinear change in M-hydrogel resistance under applied strain at low pH conditions. When the ionic current dominates, we get nonlinearity in ΔR versus strain. Credit: DOI: 10.1002/smtd.202100819

Ultrathin nanomaterials, known as MXenes, are poised to make it easier to monitor a person's well-being by analyzing their perspiration.

While they share a similar two-dimensional nature to graphene, MXenes are composed of nontoxic metals, such as titanium, in combination with carbon or nitrogen atoms. With naturally high conductivity and strong surface charges, MXenes are attractive candidates for biosensors that can detect small changes to chemical concentrations.

In 2019, Husam Alshareef's group developed a MXene composite electrode, which they enclosed in a wearable armband sensor. The device, which had a modular design that used MXene inserts loaded with appropriate enzymes, could absorb perspiration and detect several analytes in human sweat, including glucose and lactic acid.

Alshareef and his colleagues, in collaboration with Sahika Inal's research team, recently tried combining MXene sheets with hydrogels—water-filled polymers that are compatible with human tissue because they are able to stretch. Intriguingly, the team found that high levels of mobile ions in the hydrogel produced strong sensitivity to the mechanical strain that occurs during exercise.

"Initially the MXene sheets are randomly oriented within the hydrogel, but once you apply pressure to them, the sheets become more horizontally oriented," explains Alshareef. "Because MXenes have a high concentration of negative charges on their surfaces, horizontal arrangements strongly affect ion movements within the hydrogel, and thus we can measure different levels of pressure change."

A prototype wearable sensor, developed with the new MXene–hydrogel compound, was able to track muscle movement by producing distinct electrical resistance patterns as mechanical stress increased. These patterns in turn changed instantly when the sensor was exposed to additional ions in the form of acidic or basic solutions.

This led the KAUST team to realize their device could be used to correlate pH changes in sweat to fatigue-inducing acid buildups in muscle cells.

"As we exercise and our muscles get tired, the sensor sees the new chemical environment and produces different electrical resistance versus stress curves," says Kang Lee, a former KAUST postdoc and lead author of the study. "By comparing these curves to reference curves for a given sensor, we can determine the pH of the sweat and how fatigued the muscle is."

With Bluetooth connectivity to nearby digital devices, the MXene-based sensor may prove valuable to athletes looking for real-time performance measurements once the technology is optimized. "The most serious challenge is the long-term stability of the sensor, so we're looking at altering compositions and designs in future experiments," says Alshareef.

More information: Kang Hyuck Lee et al, Muscle Fatigue Sensor Based on Ti3C2Tx MXene Hydrogel, Small Methods (2021). DOI: 10.1002/smtd.202100819