The team used in situ micromechanical testing combined with synchrotron X-ray techniques. Credit: University of Surrey

By using the synchrotron at Diamond Light Source in Oxfordshire, the team were able to complete sophisticated examinations of the characteristics of cell structures at a nano level and even at an atomic scale and to investigate how cells and materials interact with each other.

To improve cancer screening and treatment, researchers need accurate models of cancer tissues on which to experiment. Previous research made significant progress in building accurate, novel 3D models which mimic features of a pancreatic tumor, such as structure, porosity and protein composition. The latest research, published in the Journal of Materials Research and Technology and Materials Today Advances, demonstrates a way to improve the mechanical characterisation and testing of those 3D structures which can ultimately lead to a better understanding of how cells interact with each other and with protein matrices at nanoscale. Ensuring that 3D structures and mechanical performance in laboratory test conditions replicate the structures and mechanical performance in cancer tissue will help scientists conduct the best possible research, with the hope of eventually developing better treatments for pancreatic ductal adenocarcinoma.

Any progress in this area is particularly welcome because, although there has been intense research effort into this particularly aggressive form of cancer, survival rates have changed little. It is the fifth leading cause of cancer-related deaths in the UK and only eight percent of patients diagnosed survive for more than five years.

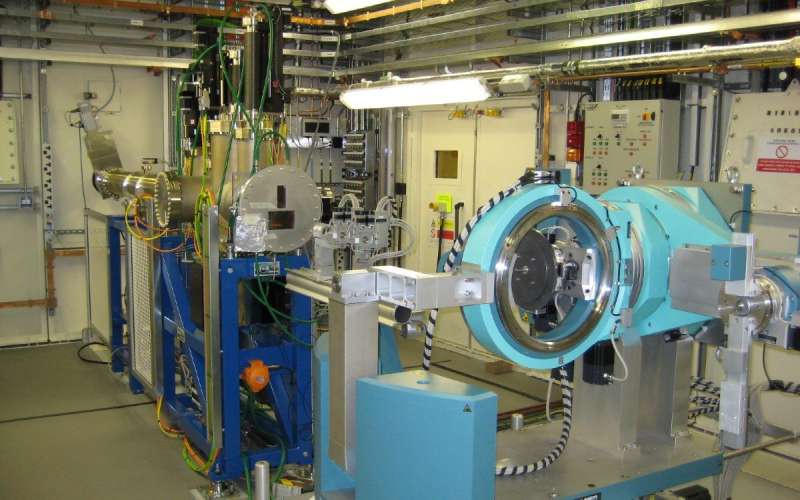

Inside the experimental hutch at Diamond’s B16 beamline. Credit: University of Surrey

The team measured stresses on the tiny lab-made structures through loading and unloading cycles and compared the impact of using different protein mixes as part of those 3D structures. They used in situ micromechanical testing combined with synchrotron X-ray techniques, allowing them to quantitatively measure the deformation mechanics and the mechanical properties of components at multiple length scales under various modified surfaces.

Dr. Jingyi Mo, research fellow in mechanical engineering sciences at the University of Surrey, said: "People often don't expect mechanical engineering to work at a nano or atomic scale, but there's such important work going on. By combining advanced mechanical characterisation of biomaterials with local scale cell behavior, we're opening doors to new scientific discoveries."

Dr. Tan Sui, senior lecturer in materials engineering, said: "By providing better cell-material characterisations, we can shed more light on the way cells interact with each other. This nano-scale analysis could help researchers use nature to inspire better tissue engineered scaffolds, a key pathway to improving screening and treatment. There's still a lot of work to do before patients benefit, but we're inching forwards in the right direction."

More information: Jingyi Mo et al, Multi-scale structural and mechanical characterisation in bioinspired polyurethane-based pancreatic cancer model, Journal of Materials Research and Technology (2021). DOI: 10.1016/j.jmrt.2021.09.041

Jingyi Mo et al, Novel in situ multi-level analysis of structural-mechanical relations in a bioinspired polyurethane-based tissue model, Materials Today Advances (2021). DOI: 10.1016/j.mtadv.2021.100184

Provided by University of Surrey