September 1, 2021 feature

Extremely strong nano-twinned pure nickel with extremely fine twin thickness

![Typical microstructure of as-deposited NT-Ni with an extremely fine twin thickness. (A) Three-dimensional structure of NT-Ni composed of plan-view and cross-sectional bright-field TEM images. (B) Twin thickness and (C) column width distributions measured from TEM and HRTEM images of the deposited NT-2.9 specimen. (D) Higher magnified cross-section TEM image of the NT-2.9 specimen. (E) HRTEM image taken along the [011] zone axis. The inset in (E) shows the corresponding selected-area electron diffraction pattern. (F) XRD pattern showing the dominant (111) orientation present in NT-2.9 specimen. a.u., arbitrary units. Credit: Science Advances, doi:10.1126/sciadv.abg5113 Extremely strong nano-twinned pure nickel with extremely fine twin thickness.](https://scx1.b-cdn.net/csz/news/800a/2021/extremely-strong-nano.jpg)

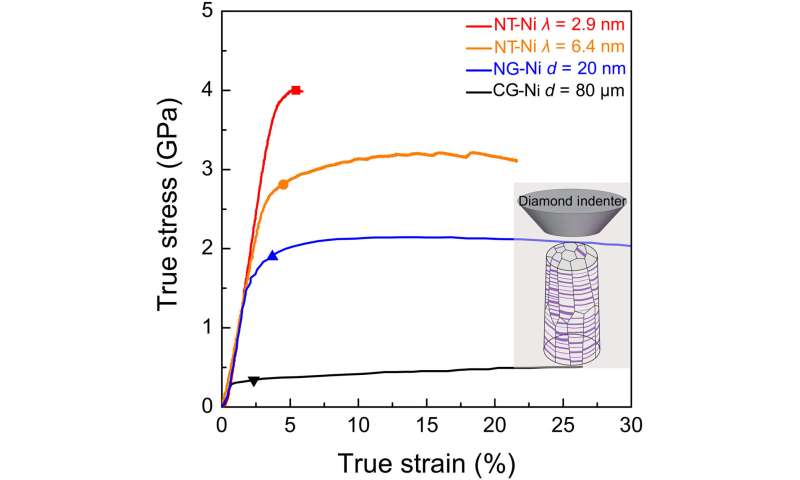

In a new report on Science Advances, Fenghui Duan and a research team in China detailed continuous strengthening in nanotwinned pure Nickel materials. The material recorded an unprecedented strength of 4.0 GPa at extremely fine twin thickness, 12 times stronger than that of conventional coarse-grained Nickel. Theories suggest diverse mechanisms of softening nanograined metals. Continuous strengthening can occur in nanotwinned metals with extremely fine twin thickness to realize ultrahigh strength. It is challenging to experimentally verify this hypothesis while regulating the synthesis of nanotwinned metals with a thickness below 10 nm. In this work, the team developed columnar grained nanotwinned nickel with twin thickness ranging from 2.9 to 81 nm, using direct current electrodeposition to show the process of continuous strengthening. Duan et al. used transmission electron microscopy (TEM) to reveal the attributes of strengthening and credited the outcomes to the fine-spaced architecture of the material.

Microstructure of the developed nanotwinned nickel

The bulk nickel specimens maintained a high purity and contained a high density of nanoscale twin lamellae embedded with nanoscale columnar grains synthesized using direct current electrodeposition in a citrate bath. The team regulated the nickel and citrate ion contents in the electrolyte to refine the average twin thickness. The material showed a narrow distribution ranging from 0.5 to 15 mm. The researchers used magnified micrographs to observe details of the materials and using X-ray diffraction patterns, they noted an out-of-plane crystallographic texture, consistent with the transmission electron microscopy results.

Mechanisms of materials development and strengthening.

The scientists then used electrodeposition as a non-equilibrium process for the widespread formation of pure nickel. The stress-relaxed nanotwinned metals were energetically more stable than the highly stressed deposits. The lower concentration ratio of citrate and nickel ion resulted in higher internal tensile stress. The team also added hydrogen to promote twin nucleation. To understand the mechanical properties of the material, they conducted uniaxial compression tests on micropillars with a diameter of 1.3 microns in scale. The stress-strain curves indicated the material with a smaller twin thickness to be stronger, showing that the strengthening behavior is still functional even with a refined twin thickness.

-

Mechanical properties of NT-Ni pillars. Uniaxial true stress-strain curves for pillars showing that the flow stress at 2% plastic strain in the NT-2.9 and NT-6.4 specimens is 4.0 and 2.9 GPa, respectively. The true stress-strain curves for NG- and CG-Ni from (22) are also presented for comparison. The red square, orange circle, and blue and black triangles denote the flow stresses at 2% plastic strain for the four samples. The inset displays a schematic of the compression test that was carried out on 1.3-μm-diameter NT-Ni specimens. Credit: Science Advances, doi:10.1126/sciadv.abg5113 -

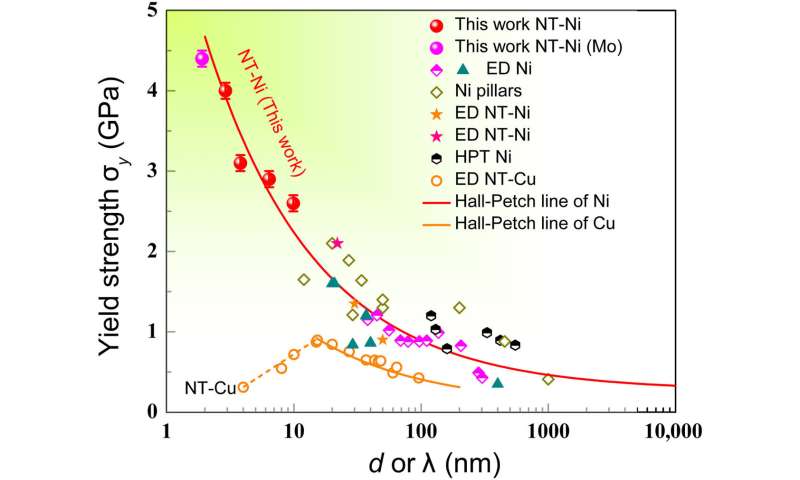

Continuous strengthening in NT-Ni. Variation in the yield strength with average grain size or twin thickness for Ni and Mo-microalloyed NT-Ni (1.3 at. %), along with literature data directly obtained by tensile and compression tests for electrodeposited (ED) Ni, Ni pillars, ED NT-Ni (22, 24–33, 53, 54), and NT-Cu (2). Continuous strengthening behavior extending to twin thickness of 2.9 and 1.9 nm is observed in the as-deposited NT-Ni and Mo-microalloyed NT-Ni specimens, respectively. Conversely, softening behavior, i.e., decreasing yield strength with decreasing grain size or twin thickness, is observed in the as-deposited NT-Cu when the average twin thickness is below 10 to 15 nm. Credit: Science Advances, doi:10.1126/sciadv.abg5113 -

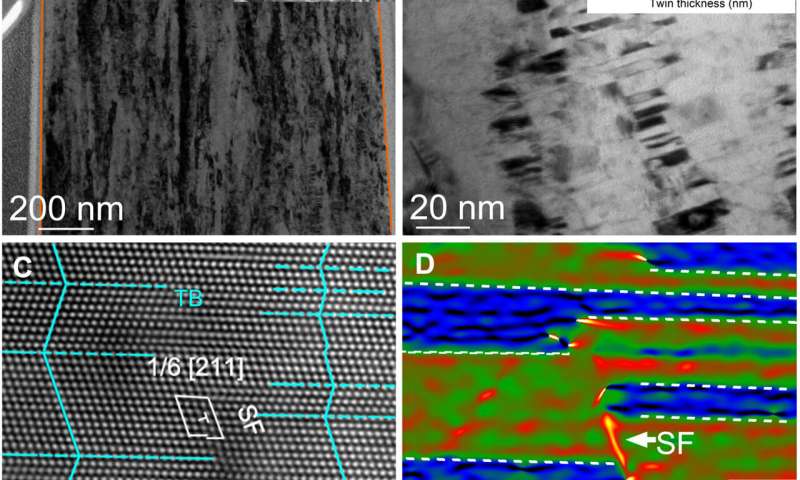

Deformation mechanisms in NT-Ni with λ = 2.9 nm. (A) Postmortem bright-field image, showing the shear band and columnar grains in the sample. The inset displays the morphology of the pillar after uniaxial compression at ~3% plastic strain. (B) A higher magnified TEM image from box R1 in (A) showing the preserved nanotwin structure in deformed regions. (C) A typical HRTEM image and (D) its corresponding GPA strain map (in-plane rigid-body rotation, ωxy) in the deformed region, showing that a partial dislocation slipped with a direction inclined to twin planes, leaving behind a stacking fault. Credit: Science Advances, doi:10.1126/sciadv.abg5113

The evolution of the microstructure and strengthening mechanisms.

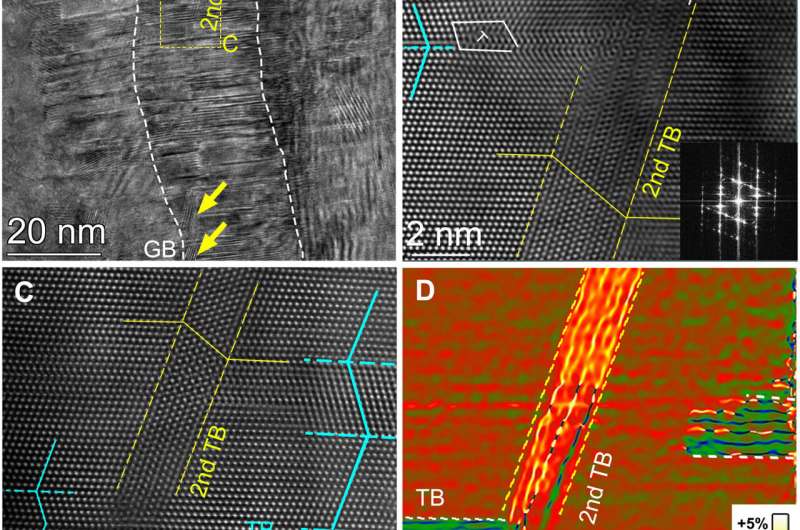

To understand the mechanisms that are responsible for continuous strengthening, Duan et al. characterized the microstructure of the material. To accomplish this, they used a three percent plastic strain on the material region and noted the consistently high density of the nanotwins despite deformation, similar to its structure prior to inducing plastic strain. This indicated a high stability of nanotwins in the material, a characteristic which arose from suppressed activity of twinning partial dislocations. The high stacking energy of the material therefore played an important role to hinder the detwinning process of the material. Duan et al. further studied the interactions using transmission electron microscopy and confirmed the strengthening mechanisms of the nanotwinned nickel material, as well as the secondary nanotwins inherent to the material, which provided it additional strength.

Outlook in materials chemistry

In this way, Fenghui Duan and colleagues showed how secondary nanotwins or hierarchical nanotwins can be formed in metals or alloys. Researchers had previously developed nucleation and growth of secondary twins and calculated the critical yield stress for twin nucleation in the specimen. Based on the model, they found the existence of a transition in the strengthening mechanism of nanotwinned Nickel at an extremely fine twin thickness. The team showed how the nanotwinned nickel achieved via direct current electrodeposition with its extremely fine twin thickness, exhibited a strength greater than those of pure nickel, derived from continuously strengthening the twin thickness.

More information: Duan F. et al, Extremely nanotwinned pure nickel with extremely fine twin thickness, Science Advances, DOI: 10.1126/sciadv.abg5113

Yip S. et al, The strongest size. Nature, DOI: 10.1038/35254

Wang J. et al, Near-ideal theoretical strength in gold nanowires containing angstrom scale twins. Nature Communications, DOI: 10.1038/ncomms2768

Journal information: Science Advances , Nature , Nature Communications

© 2021 Science X Network