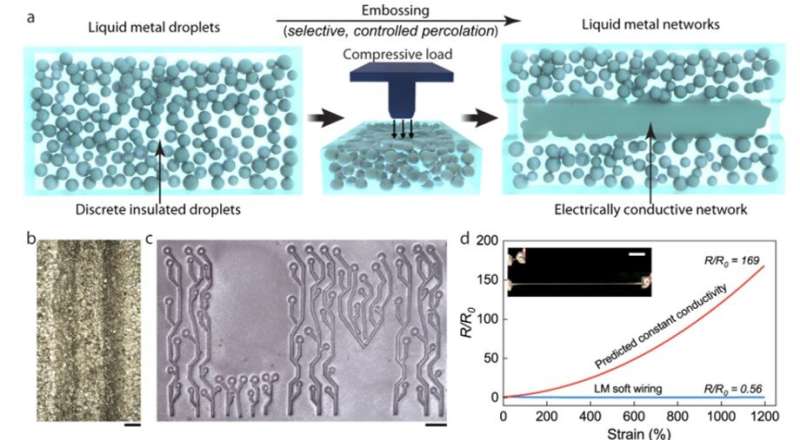

Creating robust conductive traces. (a) Schematics to illustrate the process of embossing, where discrete insulating droplets of liquid metal are selectively embossed to form a connected conductive network. (b) Optical micrograph of an embossed region shows the distressed composite, which is electrically conductive, scale bar—250 μm. (c) Embossed pattern in the form of letters L and M with intricate lines and connections (scale bar—10 mm). (d) A plot of R/R0 vs. applied strain on a conductive trace (ϕ = 60%, δ = 10%). The red curve shows the predicted R/R0 increase with applied strain for a metallic conductor, while the embossed liquid metal conductive trace (blue curve) shows constant or a reduction of R/R0 (0.56 at 1200% strain compared to 169 for the prediction). The inset shows images of an unstrained sample and a sample at 1200% strain (scale bar—50 mm). Credit: Nature Communications Materials, 10.1038/s43246-021-00169-4

Soft electronics are increasingly in demand for diverse applications, but they lack rigid enclosures and are therefore susceptible to premature disposal after electronic applications. It is therefore necessary to create soft and stretchable materials with resilient and regenerative properties. Skin-like electronics that can stretch up to 1200 percent strain with minimal change in electrical resistant can retain electrical conductivity. In a new study, Ravi Tutika and colleagues in Mechanical Engineering in the U.S., developed soft composites with adaptive liquid metal microstructures for a range of applications in practice.

Biologically inspired applications in the lab.

Soft electronics form important components across emerging fields including wearable electronics to prevent sustained damage and create tunable systems that survive diverse application spaces. Robust electronics are self-healing and damage tolerant; therefore, researchers aim to build regenerative functions for biologically inspired, recyclable applications in the lab. Scientists have already developed transient electronics that dissolve after a period of time with geometrically patterned conductors for stretchability. Liquid metal-based electronics can also be manually repaired and formed using discrete liquid metal droplets with scribing/writing or laser sintering. In this work, Tutika et al. developed a liquid metal-elastomer composite as a regenerative soft platform by reconfiguring the liquid metal droplet microstructure. The regenerative electronics developed in this work, presents a tunable platform for resilient and recyclable circuits with diverse applications.

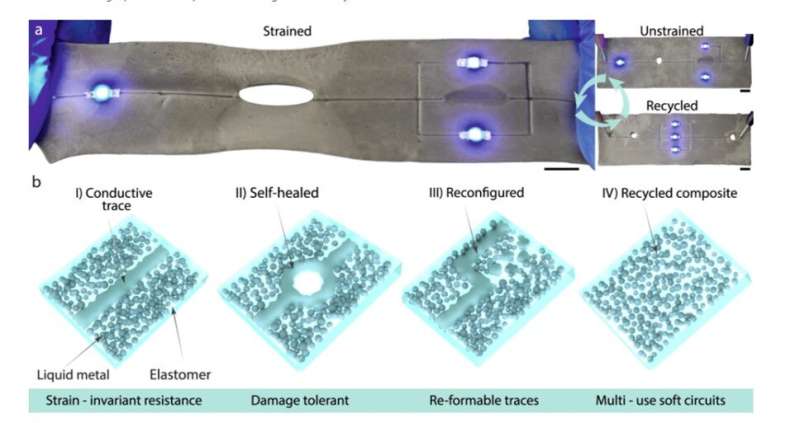

Liquid metal composites for regenerative electronics. (a) A liquid metal composite demonstrated as a singular system for soft circuits with robust, self-healable conductive traces with strain-invariant resistance at different resistance levels. Unstrained and recycled samples show the LEDs functioning before stretching and after recycling (scale bars—10 mm). Material composition ϕ = 60%, δ = 20%. (b) Schematics show the transformation of liquid metal microstructure to enable the above capabilities—strain-invariant resistance of a conductive trace created through embossing to form a network of liquid metal particles. Damage tolerant traces through an autonomous reconfiguration of liquid metal particle connections for self-healing electronics. Reformable traces are enabled by erasing a previously formed liquid metal network and creation of a new network through a solvent erase approach. Multiuse soft circuits through dissolving the composite, which erases all liquid metal networks and electrical traces, and recycling for use in new applications. Credit: Nature Communications Materials, 10.1038/s43246-021-00169-4

Developing the material

To prepare the elastomer, Tutika et al. added polybutadiene (PBD) as a plasticizer for mechanical and embossing properties. The plasticizer displayed several key characteristics including a soft, highly malleable, tough microstructure with recyclable properties. The team used a solution processing approach to dissolve the solid pellets in toluene and then added plasticizer into the mix. They also added liquid metal to the solution to create an amalgamate of micron-sized liquid metal droplets. The team then calculated the initial electrical conductivity of the setup and highlighted the electrical performance of the composite conductors. The synchronous setup allowed them to tune the resistance and applied load. The method facilitated the development of highly stretchable resistors with a nearly constant resistance. To demonstrate their function, Tutika et al. also created an LED circuit and interfaced the composites with rigid electrical components.

-

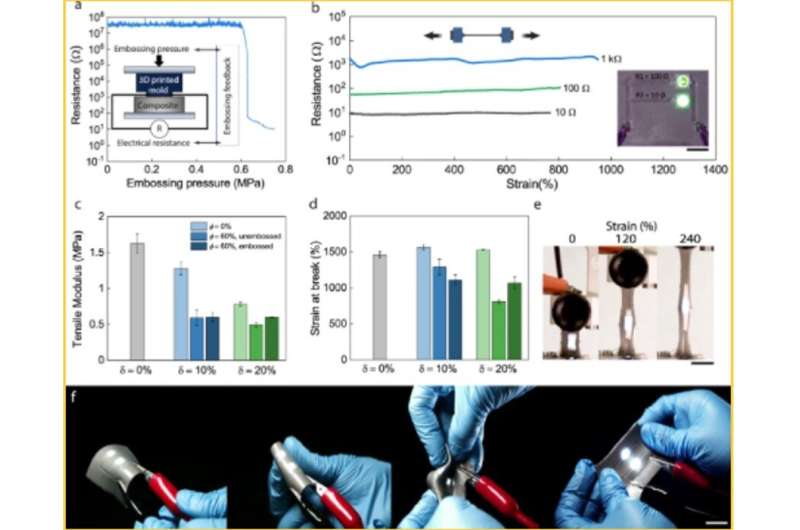

Electromechanical properties of the soft conductive traces. (a) A plot and schematic illustrates the embossing procedure with feedback control. (b) A plot of resistance vs. applied tensile strain of three different conductive traces embossed to resistances R = 10 Ω, 100 Ω, and 1 kΩ (ϕ = 60%, δ = 20%). The inset shows a photograph of embossed traces with R1 = 100 Ω and R2 = 10 Ω being used as resistors to change LED brightness (scale bar—5 mm). (c) Tensile modulus and (d) strain at break of an unfilled elastomer, pristine (unembossed), and embossed composite. (e) Stretching of an LED integrated with embossed traces (scale bar—10 mm). (f) A composite with ϕ = 50% used to create an LED circuit to illustrate the robustness of the traces in operation—bending, folding, twisting, and stretching (scale bar—10 mm). Error bars denote standard deviations for n = 3. Credit: Nature Communications Materials, 10.1038/s43246-021-00169-4

-

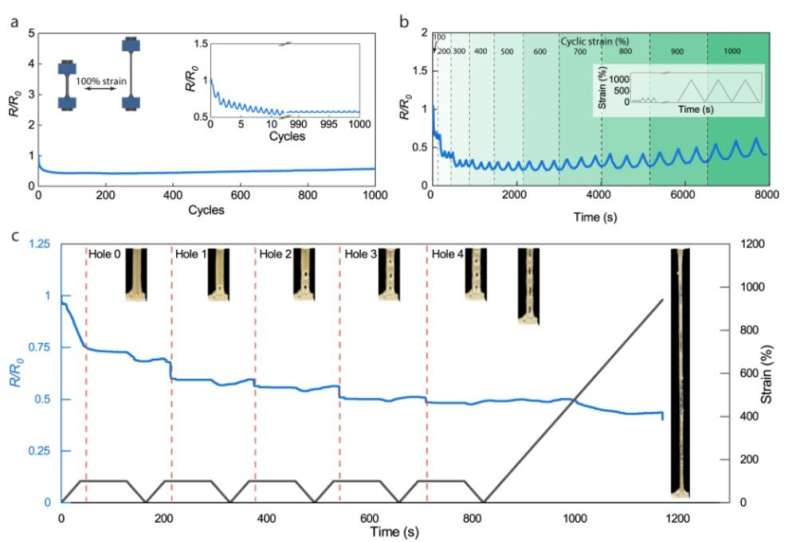

Robust operation and dynamic self-healing. (a) Plot shows the robust cyclic behavior of the composite over 1000 cycles, each up to a 100% strain. (b) Plot of R/R0 vs. time in a cyclic test of three cycles at each step up to a strain of 1000% in 100% strain increments (shading indicates the three cycles at a given strain), inset shows the applied strain profile vs. time. (c) Hole-punch test during tension shows the dynamic self-healing capability. A plot of R/R0 with respect to strain and time shows the reduction in resistance, but shows no loss in electrical conductivity. The composition for all samples in this figure is ϕ = 60%, δ = 10%. Credit: Nature Communications Materials, 10.1038/s43246-021-00169-4

Robust functionality of the composite material

The scientists then used the materials to conduct conductive traces and to perform tensile tests. The results highlighted the embossed conductive traces as promising candidates for soft circuit wiring, the material also showed self-healing properties in rugged environments due to its robustness. To build the soft circuit, the team used conductive traces made on a liquid metal-elastomer-plasticizer composite sheet at predetermined locations with 3D printed molds. During the experiments, Tutika et al. showed how the constructs retained electrical conductivity and mechanical strength. The dissolvable nature of the polymer in toluene allowed the circuit to be reconfigurable for practical applications with LED light sources. The setup provided an important feature of the non-destructive composite system. The thermoplasticity of the material coupled with the liquid nature of the metallic material also allowed Tutika et al. to effectively recycle and reuse the composites. The recycled samples were electrically insulating, and they can be recycled as composites to create electrical circuits. The team showed this capability by creating functional LED circuits to indicate the reliability of electrical connections in the pristine, recyclable material samples.

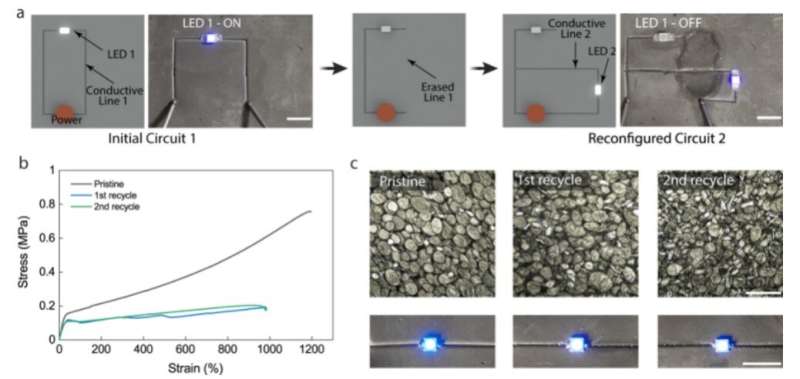

Reconfiguration and recycling of liquid metal soft composite. (a) Schematics and photographs showing the reconfiguration process of a conductive trace by solvent erase approach in a composite with ϕ = 60%, δ =20%, scale bars—10 mm. (b) Stress–strain curves of the pristine, and recycled samples showing a higher stress level for the pristine. (c) Optical micrographs show the change in liquid metal droplet microstructure with recycling and the LEDs show no loss of electrical functionality in a composite with ϕ = 60%, δ = 10% (scale bar for micrographs—100 μm and images—10 mm). Credit: Nature Communications Materials, 10.1038/s43246-021-00169-4

Outlook

In this way, Ravi Tutika and colleagues developed self-healing and recyclable soft electronics that can be stretched to high strains for robust functionalities across emerging fields of soft and stretchable electronics. The research is relevant for soft functional materials, where a single multifunctional composite system can maintain properties for soft electronics, including robust stretchability, healing capacity and recyclability. During the development of the material constructs, the team used unique liquid phase inclusions to reconfigure the microstructure of the material and form robust liquid metal networks to build resilient and regenerative electronics. The material is also applicable for diverse functionalities, allowing materials scientists to reduce electronic waste alongside improved recyclability.

More information: Self-healing liquid metal composite for reconfigurable and recyclable soft electronics, Tutika R. et al. Communications Materials, doi.org/10.1038/s43246-021-00169-4

Rogers J. et al. Biomedical devices go wild. Science Advances, 10.1126/sciadv.aav1889

Bartlett M.D. et al. Self-healing materials for soft-matter machines and electronics, NPG Asia Materials, doi.org/10.1038/s41427-019-0122-1

Journal information: Science Advances

© 2021 Science X Network