Complex structures of transparent fused silica fabricated via injection molding of the newly developed Glassomer composite. Credit: Glassomer GmbH

Glass is ubiquitous in high-tech products in the fields of optics, telecommunications, chemistry and medicine, and in everyday objects such as bottles and windows. However, shaping glass is mainly based on processes such as melting, grinding or etching. These processes are decades old, technologically demanding, energy-intensive and severely limited in terms of the shapes that can be realized. For the first time, a team led by Prof. Dr. Bastian E. Rapp from the Laboratory of Process Technology at the Department of Microsystems Engineering at the University of Freiburg, in collaboration with the Freiburg-based start-up Glassomer, has developed a process that makes it possible to form glass easily, quickly and in almost any shape using injection molding. The researchers presented their results in the journal Science.

"For decades, glass has often been the second choice when it comes to materials in manufacturing processes because its formation is too complicated, energy-intensive and unsuitable for producing high-resolution structures," explains Rapp. "Polymers, on the other hand, have allow all of this, but their physical, optical, chemical and thermal properties are inferior to glass. As a result, we have combined polymer and glass processing. Our process will allow us to quickly and cost-effectively replace both mass-produced products and complex polymer structures and components with glass."

Injection molding is the most important process in the plastics industry and enables the fast and cost-effective production of components in so-called high-throughput in almost any shape and size. Transparent glass could not be molded in this process until now. With the newly developed Glassomer injection molding technology from a special granulate designed in-house, it is now possible to also mold glass in high throughput at just 130 °C. The injection-molded components from the 3D printer are then converted into glass in a heat treatment process: The result is pure quartz glass. This process requires less energy than conventional glass melting, resulting in energy efficiency. The formed glass components have a high surface quality, so that post-treatment steps such as polishing are not required.

-

Transparent fused silica gears produced by injection molding of the newly developed Glassomer composite. Credit: Glassomer GmbH

-

Injection molding of the newly developed Glassomer composite enables the production of transparent fused silica beakers. The beakers are filled with dyed water or fluorescent liquids. Credit: Glassomer GmbH

The novel designs made possible by Glassomer's glass injection molding technology have a wide range of applications from data technology, optics and solar technology to a so-called lab-on-a-chip and medical technology. "We see great potential especially for small high-tech glass components with complicated geometries. In addition to transparency, the very low coefficient of expansion of quartz glass also makes the technology interesting. Sensors and optics work reliably at any temperature if the key components are made of glass," explains Dr. Frederik Kotz, group leader at the Laboratory of Process Technology and Chief Scientific Officer (CSO) at Glassomer. "We have also been able to show that micro-optical glass coatings can increase the efficiency of solar cells. This technology can now be used to produce cost-effective high-tech coatings with high thermal stability. There are a number of commercial opportunities for it."

-

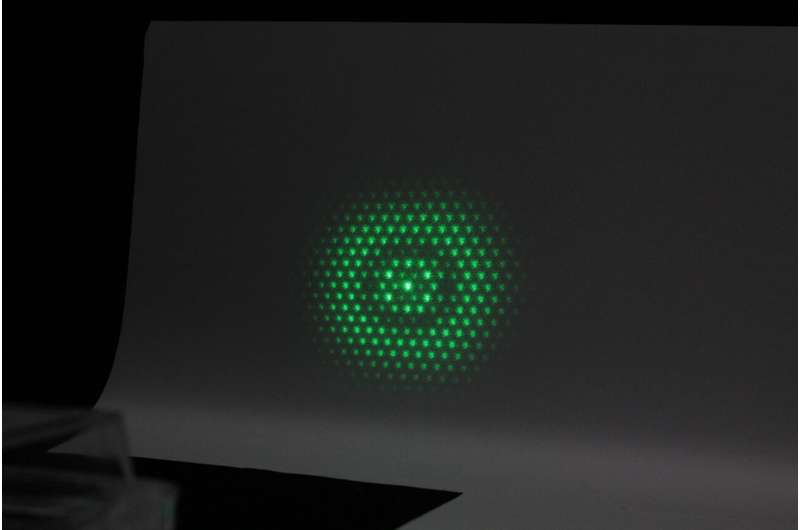

Characteristic light refraction pattern when the microstructure is illuminated with a laser. Credit: Glassomer GmbH

-

Glassomer injection molding granules and injection molded structures. Credit: Glassomer GmbH

The team around Frederik Kotz and Markus Mader, a doctoral student at the Laboratory of Process Technology, solved previously existing problems in the injection molding of glass such as porosity and particle abrasion. In addition, key process steps in the new method were designed to use water as the base material, making the technology more environmentally friendly and sustainable.

More information: High-throughput injection molding of transparent fused silica glass. Science, DOI: 10.1126/science.abf1537

Journal information: Science

Provided by University of Freiburg