Credit: ACS

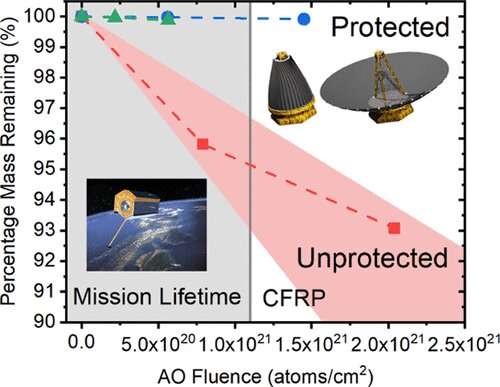

Atomic oxygen is created when O2 molecules break apart, a process made easier in space because of the abundance of ultraviolet radiation. According to NASA, 96 percent of low-Earth orbit's atmosphere is atomic oxygen, a reality that caused problems in NASA's early space shuttle missions.

In a paper published by the journal ACS Applied Materials & Interfaces, the team from Surrey's Advanced Technology Institute and Airbus detail how they developed a nano-barrier and custom-built deposition system that bonds to the surface of polymer or composite materials, protecting them from erosion in low-Earth orbit.

The new cutting-edge nano-barrier allows for large-area, conformal coating on complex 3-D structures such as spacecraft and optical mirrors. This eliminates the risk of contamination and the need to wrap instruments with multi-layer insulation, opening up opportunities to increase satellite performance.

Professor Ravi Silva, Director of the Advanced Technology Institute at the University of Surrey, said: "After exhaustive simulation testing and nearly a decade of collaborative research, we are delighted to reveal the most advanced solution yet to protecting satellites and spacecraft. Our nano-scale coating guards against the damaging effects of UV radiation and atomic oxygen that has plagued space travel."

Christopher Hess, Head of Microwave Instruments at Airbus Space Systems, said: "This breakthrough technology is an enabler for extremely agile, high performance space borne radar missions. It should have a huge positive impact on overall mission performance by offering higher flexibility in the acquisition as well as increasing the possible imaged area—giving our instruments greater performance."

The teams from Airbus and Surrey's Advanced Technology Institute are now working on the next stage leading to industrialisation of the coating to enable the first LEO missions to be treated from 2022.

More information: Christopher T. G. Smith et al. Complete Atomic Oxygen and UV Protection for Polymer and Composite Materials in a Low Earth Orbit, ACS Applied Materials & Interfaces (2021). DOI: 10.1021/acsami.0c21552

Journal information: ACS Applied Materials and Interfaces

Provided by University of Surrey