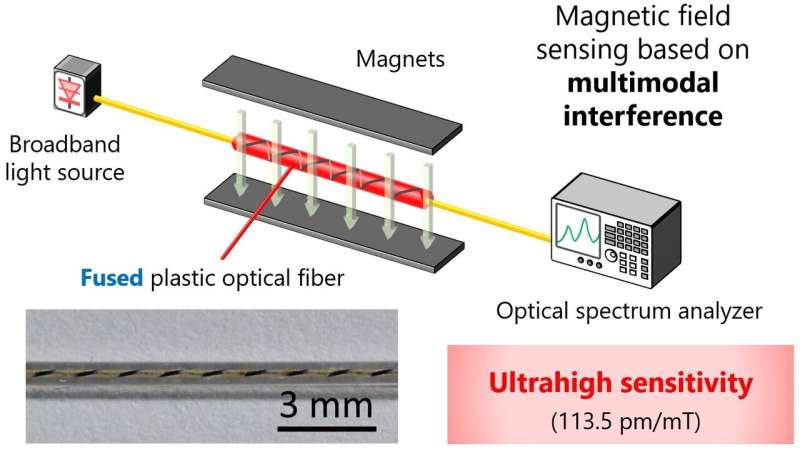

A magnetic field sensor based on multimodal interference in a "fused" polymer optical fiber achieves an ultrahigh sensitivity of 113.5 pm/mT. Credit: Yokohama National University

The invention of optical fibers has revolutionized not only telecommunications but also sensing technology. Optical fiber sensors can measure strain, temperature, pressure, and many other physical parameters along the fibers, but they are currently immune to electromagnetic noise—interference from other external electric or magnetic interactions. It is a desirable trait, until the effect of the electromagnetic field on the fibers needs to be measured. Now, an international team of researchers has used what was previously considered a 'damaged' part of an optical fiber to develop such a magnetic field sensor.

They published details of their approach on Nov. 5 in Advanced Photonics Research.

"This nature of immunity to electromagnetic noise is a great merit when we measure strain, temperature, etc., under strong electromagnetic field environments," said paper co-author Yosuke Mizuno, associate professor at the Faculty of Engineering, Yokohama National University. "However, it simultaneously means that electromagnetic field sensing using optical fibers is a major challenge, which we tackled in this paper."

The researchers took advantage of a 'fiber fuse' effect, which is induced when high-power light is injected into an optical fiber with tight bends, bad connectors, and other non-ideal conditions. When high-power light is injected into such a compromised optical fiber, the optical energy is 'trapped' in the core of the fiber, generating an optical discharge that propagates toward the light source, permanently damaging the fiber in the process. The research team has found that, when the fiber is made of polymer, this effect results in an electrically conductive carbonized path, which can in turn enable the interactions needed to react to magnetic fields.

"The interactions between the magnetic field and the carbonized—or 'damaged'—regions can lead to variations in optical parameters in the fiber," said lead author Arnaldo Leal-Junior, professor in the Graduate Program in Electrical Engineering, Federal University of Espírito Santo. "By sandwiching a fused polymer fiber between two silica single-mode fibers and inducing what we call multimodal interference, a fiber-optic magnetic field sensor can be implemented."

The researchers experimentally showed that this sensor can detect a small magnetic field change of 45 microtesla, which is several hundreds of times smaller—or more sensitive—than the 20 millitesla detection by a conventional fiber-optic method. For comparison, a magnetic field of about 100 microtesla is measured an inch away from an operating kitchen microwave.

"Magnetic field sensors are often required in handling various apparatuses in electric power systems, such as generators and motors," Mizuno said. "We anticipate that the merits of our sensor, including electrical insulation and long measurement range, can be exploited in such applications."

-

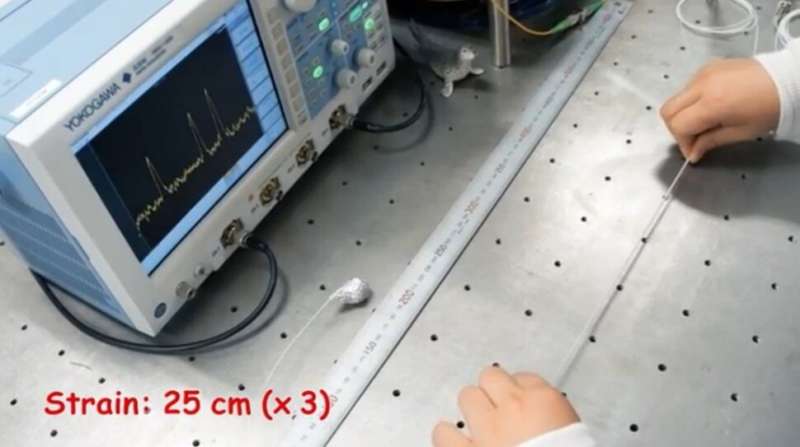

Strain distribution along a sensing fiber can be measured in real time. Credit: Yokohama National University

-

Photographs were taken at 1-s intervals. The light was injected from the right-hand side, while the fuse propagated from the left-hand side. Credit: Yokohama National University

Leal-Junior also noted that the proposed sensor can be easily fabricated at a low cost and that their approach paves the way for a novel recycling option by salvaging fused polymer optical fibers for use in magnetic field sensors.

The researchers are planning to improve the measurement accuracy as well as further enhance the sensitivity of the proposed sensor. They will also attempt to use the same approach to demonstrate electric field sensing in the near future.

More information: Arnaldo Leal-Junior et al, Highly Sensitive Fiber‐Optic Intrinsic Electromagnetic Field Sensing, Advanced Photonics Research (2020). DOI: 10.1002/adpr.202000078

Provided by Yokohama National University