Credit: Tohoku University

Pore size in porous materials affects the property of the material. For example, small pores create more absorbent surface areas. Silica gel, which is often used in food packaging to soak up moisture, is one typical example.

Recent studies on porous materials have led to the development of new materials with designable pores, affording scientists with greater control over the properties of such materials.

MOF is a porous material made up of metal ions coordinated by organic linking molecules. Well-ordered nanopores in MOFs have potential applications in material science and pharmacology.

Despite a growing interest in MOFs, researchers have yet to establish an effective method for forming MOF into thin films. Most studies on MOF preparation focus exclusively on the powdered form. Forming MOF into thin films opens up its use for humidity sensing, gas sensing and resistive switching devices.

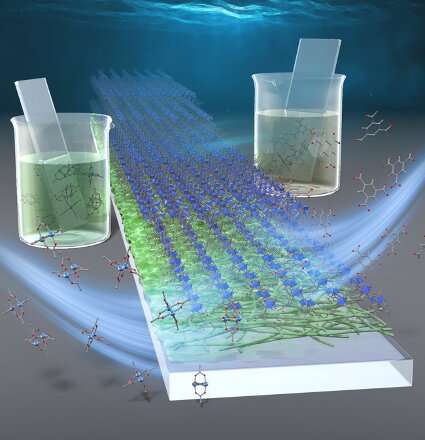

Researchers from Tohoku University, Iwate University and the Japan Synchrotron Radiation Research Institute (JASRI) overcame this obstacle by controlling the growth of MOF into films. This involved a simple "layer-by-layer" method, which uses sequential immersing of substrates into ingredient solutions.

The research group chose four types of commonly used plastic materials as a substrate for MOF film growth. They cultivated the growth of MOF films on plastic materials such as nylon and acrylic resin.

"The facile and versatile fabrication techniques used in this study have opened up MOFs to new application fields such as sensors and memory devices," said Shunsuke Yamamoto, co-author of the study. "We hope our research serves as the starting point for using MOF films with electronic devices."

Further studies on the film growing mechanism are expected to provide important insights into the coating on flexible and transparent plastic substrates under ambient conditions.

More information: Hiroaki Ohara et al. Layer-by-Layer Growth Control of Metal-Organic Framework Thin Films Assembled on Polymer Films, ACS Applied Materials & Interfaces (2020). DOI: 10.1021/acsami.0c13016

Journal information: ACS Applied Materials and Interfaces

Provided by Tohoku University