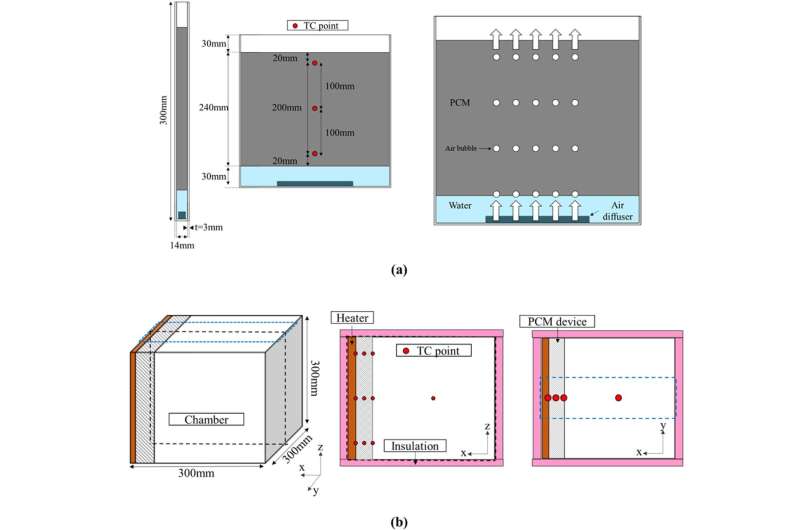

(a) PCM wall cross section (b) temperature measurement position. Credit: Korea Institue of Science and Technology(KIST)

With the summer heat becoming increasingly unbearable and prolonged due to climate change, the cooling load in the summertime has also been on the rise. Insulation is currently the primary solution for blocking heat from entering a building, but applying an additional material that delays heat penetration can suppress the indoor temperature from rising and in turn lower the cooling load of the building.

A research team in Korea has developed a new material for building walls that can reduce the penetration of heat from the outside. The team directed by Dr. Sarng Woo Karng from the National Research Agenda Division of the Korea Institute of Science and Technology (KIST) has successfully lowered heat penetration through building walls by applying a phase change material (PCM).

PCMs are materials that absorb or release heat from/to the surrounding area but do not change temperature during phase change. One of the most common types is paraffin oil, which is used to make candles. A solid PCM absorbs heat as it transitions into the liquid phase, so by using a case to hold it when it is in liquid phase without causing any leakage, it is possible to apply them to a building wall to block heat from entering inside.

The problem, however, is that PCMs do not melt evenly from the outside toward the inside during phase transition from solid to liquid. To be more specific, PCMs turn into liquid starting from the outermost layer, and the parts that are hot move upward, while the parts that are still relatively cool move downward. Thus, while the upper part may have completely melted, the lower part does not, and as a result, heat will penetrate into the building through the area where the PCM is in liquid phase. Ultimately, the PCM becomes ineffective in controlling the indoor temperature and is rendered useless.

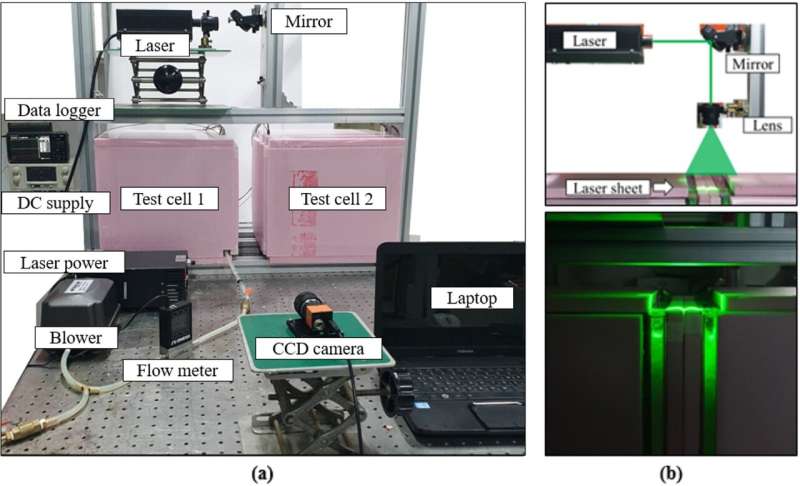

(a) the experimental device (b) the laser module for fluid flow visualization. Credit: Korea Institue of Science and Technology(KIST)

Dr. Karng's team addressed the non-uniform phase change with bubble injections. Injecting bubbles into the bottom part of the PCM during its phase transition enabled uniform circulation of the PCM in liquid phase. As a result, the PCM melted from the area closest to the envelope in a uniform manner, and heat penetration was inhibited across the building wall until the entire PCM melted.

Dr. Karng said, "We expect that the insulating wall using the PCM bubble generator used in this study will contribute to reducing the amount of energy used to heat or cool a building. Insulation techniques using PCMs helps reduce heat penetration, in combination with the building insulating material, and it can also be used as the outer walls of zero-energy buildings."

More information: Sung Ho Choi et al, Heat penetration reduction through PCM walls via bubble injections in buildings, Energy Conversion and Management (2020). DOI: 10.1016/j.enconman.2020.113187

Provided by National Research Council of Science & Technology