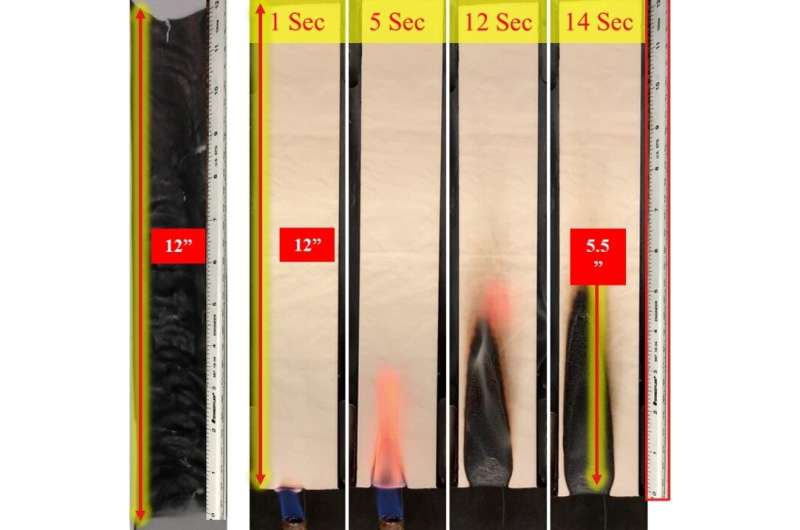

In a test, untreated fabric (left-hand panel) burns completely after a flame is removed, whereas fabric treated with phytic acid (right panels) is self-extinguishing in seconds after the ignition source is removed. Credit: Sourabh Kulkarni

Uniforms of U.S. Army soldiers must meet a long list of challenging requirements. They need to feel comfortable in all climates, be durable through multiple washings, resist fires and ward off insects, among other things. Existing fabrics don't check all of these boxes, so scientists have come up with a novel way of creating a flame-retardant, insect-repellent fabric that uses nontoxic substances.

The researchers will present their results today at the American Chemical Society (ACS) Fall 2020 Virtual Meeting & Expo.

"The Army presented to us this interesting and challenging requirement for multifunctionality," says study leader Ramaswamy Nagarajan, Ph.D. "There are flame-resistant Army combat uniforms made of various materials that meet flame retardant requirements. But they are expensive, and there are problems with dyeing the fabrics. Also, some of the raw materials are not produced in the U.S. So, our goal was to find an existing material that we could modify to make it flame retardant and insect repellent, yet still have a fabric that a soldier would want to wear."

Because Nagarajan's research group focuses on sustainable green chemistry, the team sought nontoxic chemicals and processes for this study. They chose to modify a commercially available 50-50 nylon-cotton blend, a relatively inexpensive, durable and comfortable fabric produced in the U.S. The material is used in a wide range of civilian and military applications because the nylon is strong and resistant to abrasion, whereas the cotton is comfortable to wear. But this type of textile doesn't inherently repel bugs and is associated with a high fire risk.

"We started with making the fabric fire retardant, focusing on the cotton part of the blend," explains Sourabh Kulkarni, a Ph.D. student who works with Nagarajan at the University of Massachusetts Lowell Center for Advanced Materials. "Cotton has a lot of hydroxyl groups (oxygen and hydrogen bonded together) on its surface, which can be activated by readily available chemicals to link with phosphorus-containing compounds that impart flame retardancy." For their phosphorus-containing compound, they chose phytic acid, an abundant, nontoxic substance found in seeds, nuts and grains.

Next, the researchers tackled the issue of making the material repel insects so that soldiers wouldn't have to spray themselves repeatedly or carry an additional item in their packs. The team took permethrin, an everyday nontoxic insect repellent, and attached it to the fabric using plasma-assisted deposition in collaboration with a local company, LaunchBay. Through trial and error, the researchers eventually got both the phytic acid and permethrin to link to the fabric's surface molecules.

Using methods to measure heat release capacity and total heat release, as well as a vertical flame test, they found that the modified material performed at least 20% better than the untreated material. They also used a standard insect repellency test with live mosquitoes and found that the efficacy was greater than 98%. Finally, the fabric remained "breathable" after treatment as determined by air permeability studies.

"We are very excited," Nagarajan says, "because we've shown we can modify this fabric to be flame retardant and insect repellent—and still be fairly durable and comfortable. We'd like to use a substance other than phytic acid that would contain more phosphorous and therefore impart a greater level of flame retardancy, better durability and still be nontoxic to a soldier's skin. Having shown that we can modify the fabric, we would also like to see if we can attach antimicrobials to prevent infections from bacteria, as well as dyes that remain durable."

More information: Simple surface functionalization method for multifunctional textiles with flame and vector protection:

Abstract

Nylon-cotton (Nyco) blends are currently used in a wide range of civilian and military applications because of its excellent strength and abrasion resistance provided by nylon, and comfort provided by cotton. However, there is a need to address the inherent flammability and insect repellency of Nyco fabric for various applications. Nyco has a potential fire risk because the cotton fibers catch fire at relatively low temperatures (ignition point ~ 350 oC) while Nylon 66 fibers tend to melt and burn continuously, adhere to the char formed by the cotton. Currently there are very few cost-effective flame retardants (FR) and insect repellent (IR) solutions available for Nyco fabrics.

A novel method to impart safer & durable flame retardant (FR) characteristics and insect repellency to Nylon-cotton blends through covalent functionalized is explored. This method combines a versatile surface chemical functionalization based on 1,1'-carbonyldiimidazole and atmospheric pressure plasma treatment. This involves the chemical functionalization of hydroxyl groups on the cotton surface using (CDI) followed by the attachment of diamine species and a biobased phosphorus-containing compound, phytic acid. The FR functionalized fabric is then treated with insect repellents such as permethrin using atmospheric pressure plasma treatment.

The surface of the functionalized fabric is characterized using Fourier transform infrared spectroscopy, the thermal analysis and FR performance of the functionalized fabric was performed using thermogravimetric analysis, microscale combustion calorimetry and vertical flame test. The insect repellency effects of the treated fabric were also studies using a modified World Health Organization Susceptibility Test.

Provided by American Chemical Society