August 6, 2020 feature

Controlling ice formation on gradient wettability surfaces for high-performance bioinspired materials

Ice-templating is a powerful technique to construct biological materials using ice nucleation and growth to obtain frozen material architectures, but scientists have been unable to control these two factors with effective methods. In a new report on Science Advances, Nifang Zhao and a team of scientists in chemical and biological engineering at Zhejiang University in China, demonstrated successive ice nucleation and preferential growth by introducing a wettability gradient on a cold finger (a laboratory device used to generate a localized cold surface). The work highlighted the ability to harness the rich designability of surface wettability patterns to engineer high-performance bulk materials with bioinspired complex architectures.

Developing bioinspired materials in the lab

Bioinspired materials based on nature, bone and teeth have long served as a source of inspiration to develop high performance structural materials. Biological materials can realize outstanding mechanical properties to build sophisticated hierarchical architectures at the nano/micro- and macroscopic levels. For example, bioengineers had developed various methods in the past to engineer nacre (iridescent layer of molluscan shell)-mimetic composites, which include freeze-casting and three-dimensional (3-D) printing. Freeze-casting, also known as ice-templating is a powerful technique with precise, architectural control, low-cost and versatility to engineer high performance nacre-mimetic composites and assemble a variety of building blocks. During the process, ice crystals can nucleate on a cold surface and grow in a preferred direction along the temperature gradient, and the team can control factors contributing to the process, to model the architecture of the resulting porous material. Zhao et al. therefore focused on surface engineering by modulating or controlling surface wettability. To accomplish this, they introduced a wettability gradient to control ice nucleation and growth on a cold surface. The work showed how surface wettability allowed to engineer bulk materials with biomimetic sophisticated architectures.

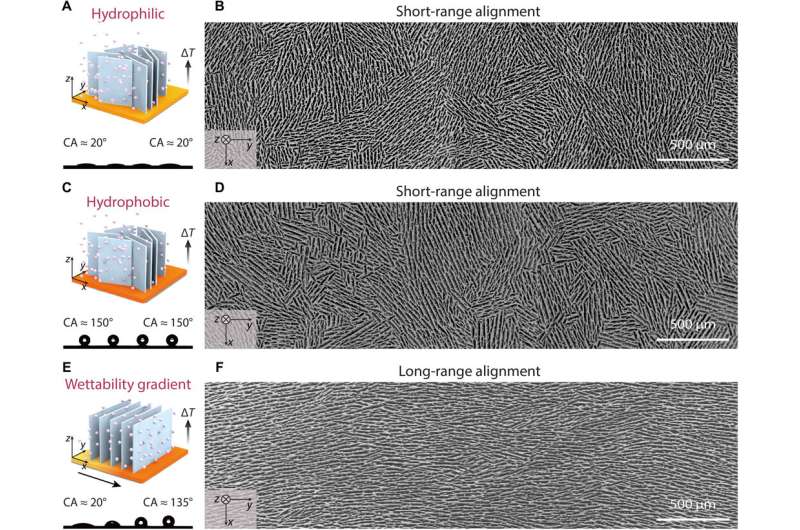

Proof-of-concept freeze-casting technique

As proof-of-concept, the team used an aqueous slurry of hydroxyapatite (HA) particles and compared freeze-casting processes on surfaces with various degrees of wettability to observe the resulting experimental microstructures. During traditional freeze-casting processes, the slurry was in direct contact with an unmodified, homogenously hydrophilic copper substrate. Upon cooling, the team generated a vertical temperature gradient to guide the preferential growth of ice crystals from the bottom to the top. Due to the hydrophilic (water-loving) nature of the copper substrate, ice nucleation occurred simultaneously across the surface, which Zhao et al. observed using scanning electron microscopy (SEM). They then repeated the same freeze-casting process on a hydrophobic copper surface. Although the ice nucleation rate delayed on hydrophobic surfaces as expected, the process occurred randomly across the entire material. Based on the same idea, the scientists designed more complex patterns for freeze-casting including copper surface modifications with silane (abbreviated POTS) via programmed dip-coating to change the surface water contact angle and wettability.

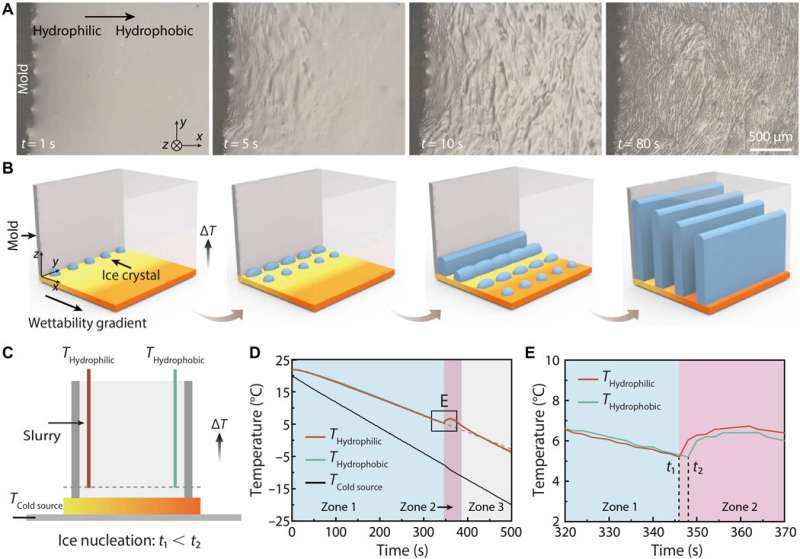

Observing the freezing process and proposing a freezing mechanism

Zhao et al. observed the freezing-casting process using an optical microscope. During the experiments they sealed a Teflon mold to a copper substrate and poured a slurry with 20 percent HA particles into the mold to observe nucleation of ice crystals from the hydrophilic region to the hydrophobic region. They credited the phenomenon to nucleation rates induced by surface wettability and studied the effects of the wettability gradient including freezing velocity and particle concentration on the microstructure.

They proposed a possible mechanism to control freeze-casted structures by controlling surface wettability. For this, the team studied the key assumptions of ice crystal nucleation and preferential growth and combined the two mechanisms to realize complex architectures in freeze-casted materials. The scientists visualized the process using a fluorescence microscope after mixing the HA slurry with a small amount of fluorescent polystyrene microspheres. The aligned particles in the medium then forced successive ice crystals to grow in similar orientations and form a long-range lamellar structure. The work suggested that surface wettability rather than the type of material determined the orientation of ice crystals.

Developing a high-performance nacre-mimetic composite and testing its mechanical properties

The scientists sintered and compounded the HA scaffold containing a long-range aligned lamellar structure with a polymer material, to generate high performance nacre-mimetic composites. The well-oriented structure mimicked the brick-and-molar architecture of natural nacre, as confirmed with micro-computed tomography. Zhao et al. maintained the particle concentration and ice growth velocity during the entire freeze-casting process to obtain large size samples with uniform structure.

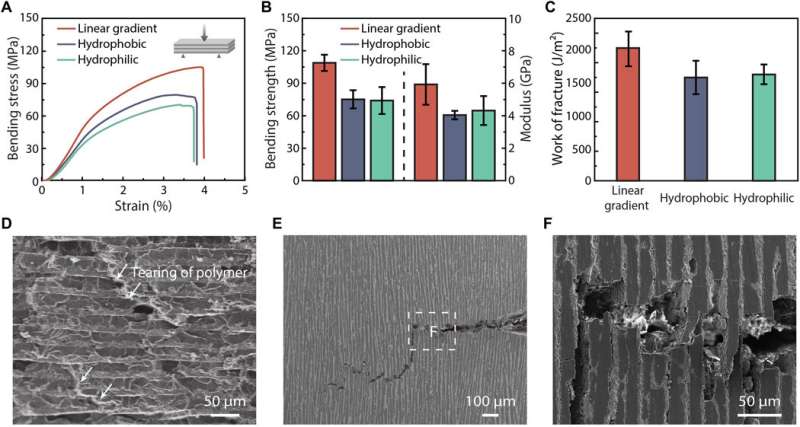

To detect the mechanical properties of the resulting structure, the team compared flexural properties of the HA/polymer composites developed by freeze-casting on gradient and homogenous surfaces. The mechanical properties of nacre-mimetic composites were superior to those prepared on homogenously hydrophobic or hydrophilic surfaces. The work showed the advantage of the long-range lamellar structure and verified freeze-casting on a gradient surface to be an effective approach to form high-performance nacre-mimetic composites.

Designing a surface-wettability pattern

The team also showed the ability to design a surface wettability pattern by freeze-casting on copper surfaces containing a bilayer linear wettability gradient and radial wettability gradient. They obtained two representative structures with cross-aligned and circular lamellar patterns, not previously possible with conventional freeze-casting techniques. Zhao et al. then analyzed the mechanical properties of the composites to understand their performance and the results confirmed the possibility of harnessing the rich designability of surface wettability patterns to build high-performance bulk materials with complex bioinspired architecture.

In this way, Nifang Zhao and colleagues showed how ice nucleation and growth could be controlled by introducing a wettability gradient onto a cold surface to control the orientation of ice crystals and the architecture of the resulting porous material. Using the concept, they obtained a long-range aligned lamellar structure and infiltrated the porous scaffold to generate a high-performance bulk nacre-mimetic composite with excellent strength and toughness. The work highlights the potential of surface wettability and its rich designability to build patterns for bioinspired complex architectures with high performance.

More information: 1. Zhao N. et al. Controlling ice formation on gradient wettability surface for high-performance bioinspired materials, Science Advances, 10.1126/sciadv.abb4712

2. Munch E. et al. Tough, bio-inspired hybrid materials, Science, 10.1126/science.1164865

3. Zhao N. et al. Superstretchable nacre-mimetic graphene/poly(vinyl alcohol) composite film based on interfacial architectural engineering, ACS Nano, doi.org/10.1021/acsnano.7b01089

Journal information: Science Advances , Science , ACS Nano

© 2020 Science X Network