Credit: King Abdullah University of Science and Technology

Membrane separations have long been recognized as energy-efficient processes with a rapidly growing market. In particular, organic solvent nanofiltration (OSN) technology has shown considerable potential when applied to various industries, such as petrochemicals, pharmaceuticals and natural products. The energy consumed by these industries accounts for 10 to 15 percent of the world's entire energy consumption.

Nevertheless, difficulties in predicting the separation performance of OSN membranes have hindered smooth transition from lab discovery to industry implementation. Predicting the performance of membranes is a challenging task because of the complex nature of solvent, solute and membrane interactions. "Despite expansive literature and reports on membrane applications, there remained no comprehensive database to guide the community," says the project leader Gyorgy Szekely from the Advanced Membranes & Porous Materials Center, King Abdullah University of Science and Technology (KAUST).

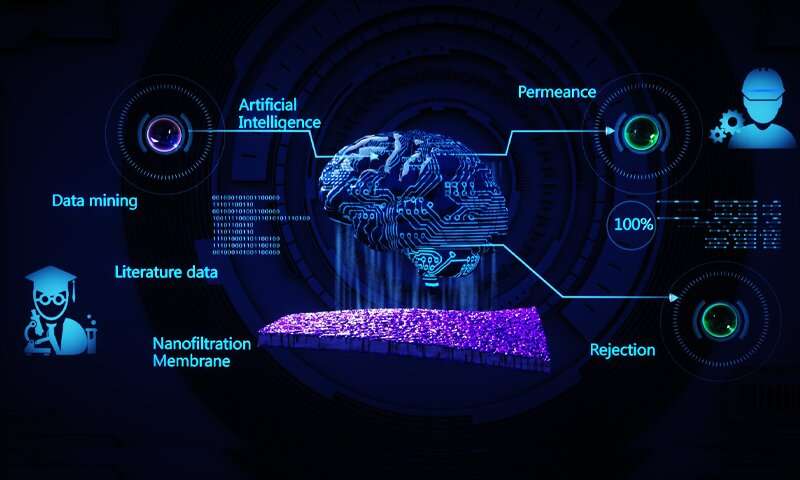

Researchers at KAUST collaborated with researchers at Incheon National University, South Korea, to develop an artificial intelligence (AI) based predictive methodology that will fast track the industrial implementation of membranes in organic media. They performed data mining to yield the largest dataset, comprising more than 38,000 datapoints in the field. Instead of approaching the problem of prediction from a fundamental mathematical perspective, they have broken away from conventions by exploiting AI. While an experienced membrane researcher can interpret complex membrane data in three dimensions (four dimensions at best), AI can analyze multidimensional data and extract hidden trends and correlations very effectively.

"To elucidate the key parameters governing membrane performance (e.g., selectivity and permeability), we performed a thorough principal component analysis with 18 dimensions," says the first author of the study Jiahui Hu. "We applied machine learning algorithms (artificial neural networks, support vector machines, and random forest models) that predicted separation performance with an unprecedented accuracy of 98% for permeance and 91% for selectivity."

Moreover, the research outcomes pave the way toward better membrane design and development. The developed performance prediction methodology will allow the in silico development of energy-efficient separations. "Ultimately, we are one-step closer to the necessary transformation from the wet lab to the wired lab," says Szekely. "The rapid identification of the right membrane for a given separation challenge will allow profit margins to be maximized by minimizing laborious experimental screenings in the lab."

More information: Jiahui Hu et al. Artificial intelligence for performance prediction of organic solvent nanofiltration membranes, Journal of Membrane Science (2020). DOI: 10.1016/j.memsci.2020.118513