July 20, 2020 feature

Self-emitted surface corrugations in dynamic fracture of silicon single crystal

![Dynamic crack front behavior in steady-state (110) cleavage of the single crystalline silicon samples under pure bending. (A) Morphologies of the (110) cleavage plane (xy plane) of the as-sawn samples at different steady-state crack propagation speeds vs. The crack propagates along the [110] direction (x axis). The Wallner lines and crack fronts are highlighted by the black and red curves, respectively. The local kinks of the crack front are highlighted by the red dashed circles and the surface corrugations are highlighted by the green lines. (B) Normalized local crack front speed vl/cR as a function of normalized vertical position y/h along the crack front, for seven experiments with different vs. Inset illustrates the sample thickness h and the angle θ that represents the local normal direction of the crack front (red curve). (C) AFM measurement of the local front kink zone shows the emergence of the surface corrugations. (D) Morphologies of the (110) cleavage plane of the surface-polished samples at different vs. Fracture surface morphologies exhibit the mirror-like feature at vs = 0.59cR and the presence of surface corrugations at vs = 0.67cR (below 0.45 ± 0.01h), 0.74cR (below 0.51 ± 0.02h), and 0.80cR (below 0.59 ± 0.02h). Credit: PNAS, doi: https://doi.org/10.1073/pnas.1916805117 Self-emitted surface corrugations in dynamic fracture of silicon single crystal](https://scx1.b-cdn.net/csz/news/800a/2020/selfemitteds.jpg)

When a dynamic crack propagates through material heterogeneities (material differences), elastic waves are emitted to disturb the crack and change the morphology of the fracture surface. When a crack propagates along preferential cleavage planes of asperity-free (roughness-free) crystalline materials, researchers expect a smooth crack front and a mirror-like fracture surface. In a new report now published on the Proceedings of the National Academy of Sciences (PNAS), Ming Wang and a research team in Mechanics at the French National Center for Scientific Research (CNRS) in France, the Huazhong University of Science and Technology and the Hubei Key Laboratory in Wuhan, China, showed characteristic crack propagation in a single crystalline silicon without material asperities (material roughness). The crack front presented a local kink during high speed crack propagation and generated periodic fracture surface corrugations or ripples. The phenomena grew from angstrom (Å) amplitude to a few hundred nanometres (nm) to propagate with a long lifetime at a frequency-dependent speed and with a scale-dependent shape. The local front oscillations presented the characteristic of solitary waves and Wang et al. named the nonlinear elastic waves "corrugation waves."

In materials science, crack propagation can lead to catastrophic material failure, and therefore, materials scientists have intensively studied the dynamic feature for decades but the details remain challenging. According to linear elastic fracture mechanics, a crack tip in a two-dimensional (2-D) medium can be described as an energy sink around which dissipation occurs for energy propagation. In 3-D systems the local crack speed is governed by local energy balance to control the whole crack front shape. In the present work, Wang et al. reported specific fracture surface corrugations in the silicon single crystal cleavage emerging in high speed cracks. They could not explain the morphology using any deflection scenarios hitherto known to describe the cleavage of silicon crystals. The team therefore proposed self-emitted corrugations (ripples) to be traces of different nonlinear elastic waves known as corrugation waves that nucleate from the fracture energy fluctuation at a critical crack speed. The corrugation waves also shared specific properties with the crack front waves. The team highlighted two intriguing attributes of corrugation waves in this work, including nonlinear dispersion and particle-like interaction dynamics.

Fracture experiments to study the surface features

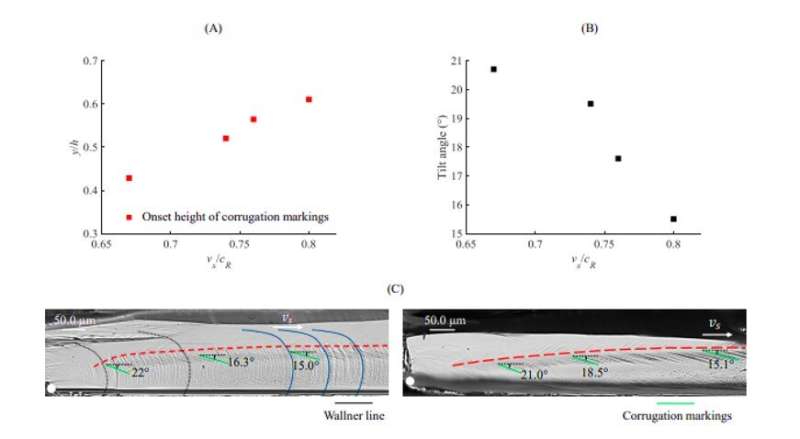

Wang et al. performed the fracture experiments on as-sawn single crystalline silicon plates under pure bending to form the (110) cleavage. The bonding stress was normal to the fracture surface to propagate under a pure opening mode. Due to various seed crack sizes, the scientists obtained a wide range of steady-state crack speeds, with a Rayleigh wave speed (crack velocity) equal to 4,460 m/s for the (110) [110] direction of the crystal, to examine crack dynamics. The invariant shape of the Wallner lines i.e. lines resulting from the propagating crack front and shear waves revealed the steady-state propagation of the whole crack front. In a low-speed scenario, the local crack speed profile monotonically decreased from the bottom to the top along the crack front, while in high-speed scenarios, the local kink translated into a fluctuation.

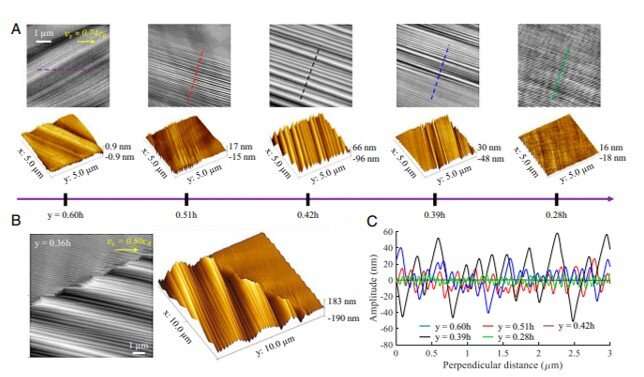

The team conducted a second series of experiments on surface-polished silicon samples, which excluded the Wallner lines to study the accurate morphological features of the fracture surface corrugations. Surface corrugations on two opposing fracture surfaces involved a peak-to-valley match, which Wang et al. distinguished from the local plasticity ahead of the crack tip presented as a peak-to-peak match, and analyzed them using atomic force microscopy (AFM) measurements. Based on five typical topographies, the research team observed the amplitude grow from an angstrom level to a maximum roughness of 100 nm. The team noted high-speed crack instability, which induced an abrupt crack path deviation to extend along the local front. The surface corrugations extended along various crystallographic directions depending on the crack speed and did not coincide with a specific crystal plane.

Different stages of crack propagation

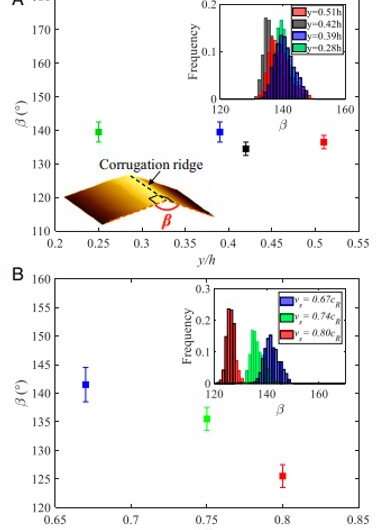

All surface corrugations exhibited a wave-like feature along the perpendicular direction, which Wang et al. measured to reveal geometrical characteristics of the corrugations. They dented the angle between the corrugation planes (denoted β) and observed its dependence on the crack speed. The surface corrugations extended along various crystallographic directions depending on the crack speed without coinciding with any specific crystallographic plane. The team revealed the long-lived propagation to be generated by highly localized out-of-plane agitations along the crack front.

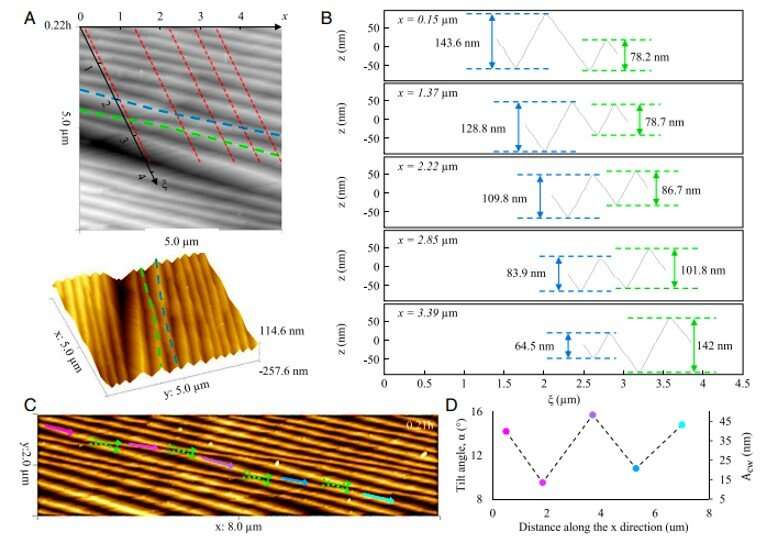

The team further investigated the characteristics of the local crack front oscillations with periodic surface corrugations, where the orientation of the corrugations (denoted α) changed with the wavelength. The α also correlated with the width of the corrugations and with nucleation triggered by high speed crack instabilities. Wang et al. observed an increased wavelength and amplitude during the growth of the crack front oscillations, which subsequently decreased during decay of the oscillations. The team then highlighted particle-like interaction behavior of the local front oscillations. For instance, when a fast-moving oscillation met a slow one, they showed particle-like collision and the fast-moving oscillation decayed and de-accelerated, while the slow oscillation grew and accelerated, meanwhile the linear correlation between the wavelength and amplitude retained.

In this way, the collision events further revealed nonlinear characteristics of crack propagation, where particle-like interactions of the front oscillations were similar to solitary waves. During the collision, the two pulses exchanged their speeds and shapes for a resulting phase shift. In this study, Wang et al. considered the front oscillations as nonlinear elastic waves and named them "corrugation waves" as they produced out-of-plane ripples (corrugations) on the fracture surface. The corrugation waves were continuously self-emitted from the moving front to propagate with the characteristics of solitary waves. The initial state of the corrugation waves depended on the source that created them. The nonlinear corrugation waves reported here differed from those described in previous through numerical modeling or experiments based on material asperities. Ming Wang and colleagues expect the results to provide additional insights on soliton-like crack front dynamics on the fracture surface of asperity-free (roughness-free) crystalline materials in materials science.

More information: Meng Wang et al. Self-emitted surface corrugations in dynamic fracture of silicon single crystal, Proceedings of the National Academy of Sciences (2020). DOI: 10.1073/pnas.1916805117

R. G. Pratt et al. Acoustic surface waves on silicon, Applied Physics Letters (2004). DOI: 10.1063/1.1652878

J. R. Kermode et al. Low-speed fracture instabilities in a brittle crystal, Nature (2008). DOI: 10.1038/nature07297

Journal information: Proceedings of the National Academy of Sciences , Applied Physics Letters , Nature

Provided by Science X Network

© 2020 Science X Network