Plastics markets adapt in the age of COVID-19

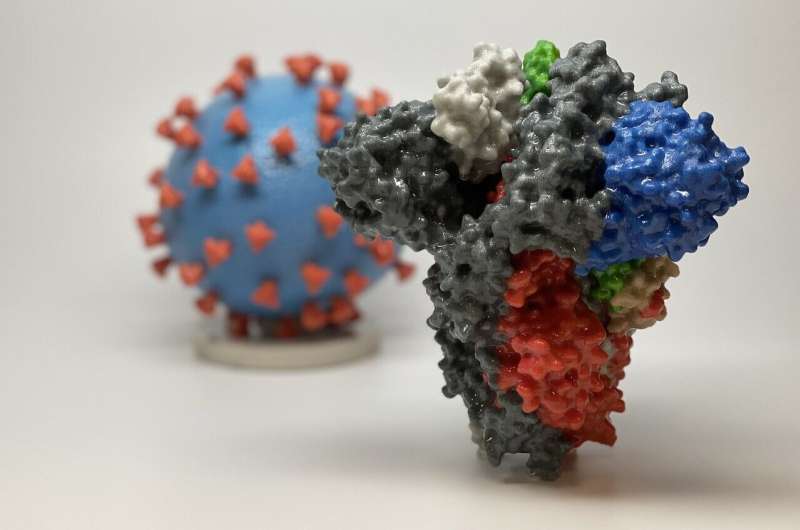

The COVID-19 pandemic has upended life around the world, leaving industries to find creative solutions to stay open and keep up with demand. The polymer industry has been especially "plastic" during this time, adapting materials and equipment to produce personal protective equipment (PPE) and more. A new article in Chemical & Engineering News, the weekly newsmagazine of the American Chemical Society, details how plastics markets have adjusted to their new realities.

The U.S. Department of Homeland Security has deemed workers in the chemical sector as essential, but at the onset of the pandemic, shutdowns and stay-at-home orders led to decreased demand for some materials, writes Senior Editor Alex Tullo. For example, industrial plants that produce plastics for automotive manufacturers saw their assembly lines go quiet, and demand for polymer-based materials used in constructing homes has cratered in recent months. In contrast, demand for food packaging, PPE and other medical equipment has skyrocketed. Consumers are purchasing more groceries to cook at home, leading to increased production of polystyrene foam for egg cartons and meat trays. And with take-out eclipsing in-restaurant dining, the need for to-go containers has increased dramatically.

The biggest pivot plastics manufacturers have made is in the medical sector. COVID-19 has led to an unprecedented need for PPE for medical practitioners, essential workers and average consumers alike. Raw materials for PPE, most of which are polymer-based, are in short supply because of the demand. Companies have retooled their production to make medical materials, including nasal testing swabs, face shields and parts for ventilators, from the raw plastics they already produce. While companies have stepped up to the plate to provide the necessary materials to keep communities safe, they are also concerned about the health and safety of their own employees. Bulk chemical plants are already largely automated and don't require close human contact, but other facilities have had to modify their procedures to ensure social distancing and proper sanitization of work areas. With these best practices in mind, manufacturers hope that their diligence and flexibility will be rewarded as the world begins to re-open.

More information: "Plastics during the Pandemic," cen.acs.org/materials/polymers … ring-pandemic/98/i24

Provided by American Chemical Society