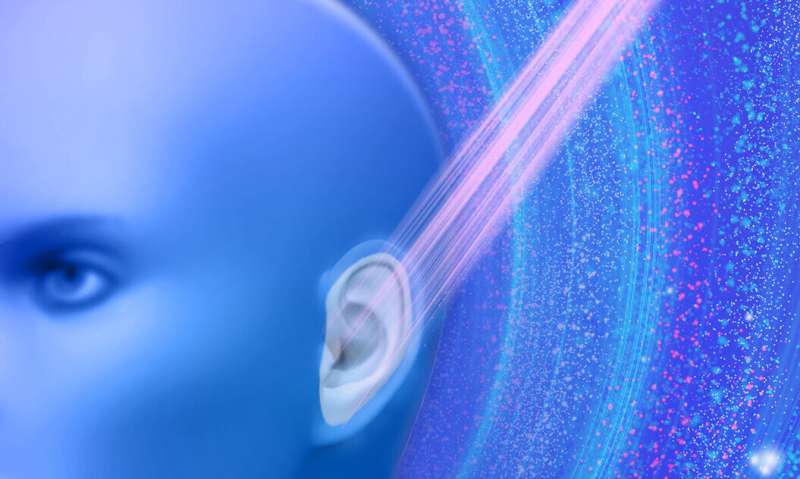

Noninvasive in vivo 3D bioprinting auricle in situ. Credit: Professor Maling Gou, State Key Laboratory of Biotherapy and Cancer Center, West China Hospital, Sichuan University.

A team of researchers with members from several institutions in China, one in the U.S. and one in Belgium, has developed a method for 3-D printing an ear inside of the body. In their paper published in the journal Science Advances, the group describes their method and how well it worked on test mice.

Three-dimensional printing has evolved over the last several years to include the use of a wide variety of materials to create products. In recent years, it has come to be used in medical applications to repair defective tissue. In such applications, ultraviolet light is used to 3-D print tissue-like material through polymerization, in which materials become denser and stick together when exposed to the light. In such efforts, surgery is required to expose the tissue that needs to be repaired. In this new effort, the researchers used near-infrared light to accomplish much the same thing, but in a way that does not require surgery.

The technique involves first injecting a bioink (made of hydrogel particles and cartilage cells) into the patient. Next, a near-infrared light beam is directed at a digital micromirror device chip, which organizes the beam of light into a desired shape—the reorganized beam is then reflected down onto the patient where it penetrates the skin and collides with the bionk inside of the body. The light beam forces the bioink to form into a desired shape and to harden—the finished product resembles the cartilage that normally forms the shape of an ear. In their testing, the team used test mice with one deformed ear—the new ear was programmed using a mirror-image of the ear that was not deformed.

A video showing noninvasive in vivo 3D bioprinting promises the fabrication of organ in situ without surgery. Credit: Professor Maling Gou, State Key Laboratory of Biotherapy and Cancer Center, West China Hospital, Sichuan University.

The researchers found that the new ear began to take shape within seconds as they applied the near-infrared light beam. The final ear shape developed over the course of a month as cartilage cells grew on the structure they had printed—the researchers described it as looking almost exactly like a natural ear. More testing is required, of course, but the researchers are optimistic that their technique will soon be used to repair human ears damaged by multiple sporting injuries or in accidents.

More information: Yuwen Chen et al. Noninvasive in vivo 3D bioprinting, Science Advances (2020). DOI: 10.1126/sciadv.aba7406

Journal information: Science Advances

© 2020 Science X Network