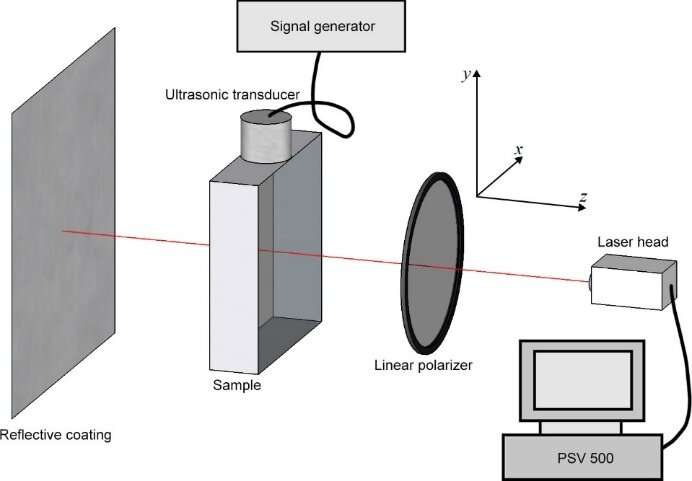

Experimental set-up of the method. Credit: IACAS

Laser doppler vibrometer (LDV) technology is used to measure the vibration of an object's surface.

In order to obtain the relationship between the measured parameters of LDV and the stress components in solids, researchers from the Institute of Acoustics of the Chinese Academy of Sciences (IACAS) proposed a new measurement method via which the stress field in the transparent solid could be measured directly based on LDV.

Compared with traditional methods, LDV has higher sensitivity and intuitiveness and could be used to observe the ultrasonic wave in transparent solid.

Additionally, it is sensitive to dynamic stress but has no response to static stress. Consequently, it wouldn't be affected by residual stress in transparent solid.

Researchers converted the measured beam emitted from LDV to linearly polarized light by adding a rotatable linear polarizer to the optical path. As a new measurement dimension, the polarization direction of laser could provide more information about the measured object.

When polarized laser light traveled into the transparent solid, the frequency of the laser, the direction of its polarization and the stress components of the internal stress field were coupled. The stress fields in the solid were precisely calculated by automatic processing of the measurement results.

Researchers used K9 optical glass with a band defect as an example. The longitudinal waves excited by the ultrasonic probe traveled down from the top of the glass block and were scattered by band defects. LDV recorded images of elastic wave at each time, including three independent stress components. Finite element analysis (FEA) results validated the new method.

The study, published in the Journal of Sound and Vibration, was supported by the National Natural Science Foundation of China.

More information: Weiyi Zuo et al. LDV-based measurement of 2D dynamic stress fields in transparent solids, Journal of Sound and Vibration (2020). DOI: 10.1016/j.jsv.2020.115288

Provided by Chinese Academy of Sciences