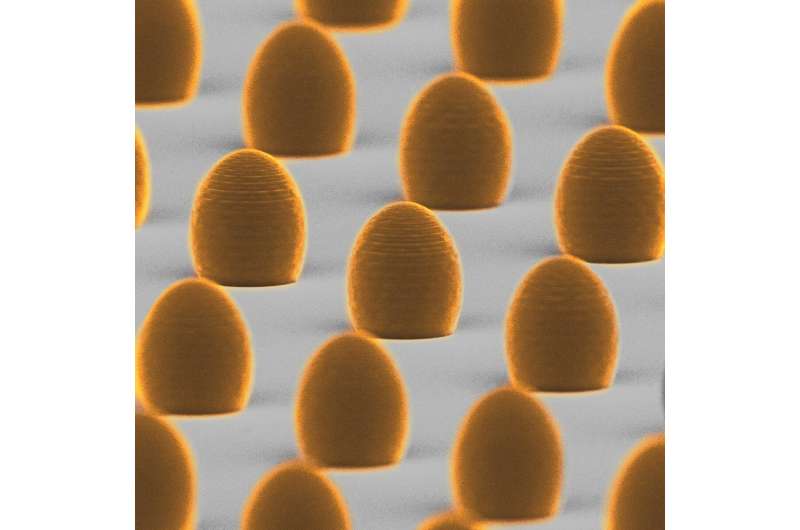

Scanning electron microscope image of 3D-printed aspherical microlenses. Thanks to short printing time, it is possible to produce hundreds of such microlenses on one sample Credit: Aleksander Bogucki, et al

Additive manufacturing is a technique in which a three-dimensional object is produced by successively adding new layers of building material to those that have already been deposited. Recently, commercially available 3-D printers have been experiencing rapid development and so have 3-D-printing materials, including transparent media of high optical quality. These advancements open up new possibilities in many fields of science and technology including biology, medicine, metamaterials studies, robotics and micro-optics.

Researchers from the Faculty of Physics, University of Warsaw, Poland, have designed tiny lenses (with dimensions as small as a fraction of a human hair diameter) that can easily be manufactured using a laser 3-D printing technique on top of various materials, including fragile novel 2-D graphene-like materials. The lenses increase the extraction of light emitted from semiconductor samples and reshape its outgoing part into an ultra-narrow beam.

Thanks to this property, there is no longer a need for including a bulky microscope objective in the experimental setup when performing optical measurements of single nanometre-sized light emitters (like quantum dots), which up to now could not be avoided. A typical microscope objective used in such a study has roughly a handbreadth size, weights up to one pound (half a kilogram) and must be placed at a distance of about one-tenth of an inch (few millimetres) from the analysis sample. These impose significant limitations on many types of modern experiments, like measurements in pulsed high magnetic fields, at cryogenic temperatures, or in microwave cavities, which on the other hand can easily be lifted by the new lenses.

The high speed of the 3-D-printing technique makes it very easy to produce hundreds of microlenses on one sample. Arranging them into regular arrays provides a convenient coordinate system, which accurately specifies the location of a chosen nanoobject and allows for multiple measurements in different laboratories all over the world. The invaluable opportunity of coming back to the same light emitter allows for much more time-efficient research and hypothesis testing. Specifically, one can entirely focus on designing and performing a new experiment on the nanoobject studied before, instead of carrying out a time-consuming investigation of thousands of other nanoobjects before eventually finding an analogue to the one in question.

The shape of the proposed microlenses can easily be adapted to the so-called 2.5-D microfabrication technique. The objects satisfying its prerequisites can be produced over large-scale surfaces by pressing a patterned stamp against the layer of material they are supposed to be made of. The 2.5-D fabrication protocol is especially attractive from the viewpoint of potential applications of the microlenses, as can be readily up-scaled, which is an important factor in possible future industrial use.

More information: Aleksander Bogucki et al, Ultra-long-working-distance spectroscopy of single nanostructures with aspherical solid immersion microlenses, Light: Science & Applications (2020). DOI: 10.1038/s41377-020-0284-1

Journal information: Light: Science & Applications

Provided by Chinese Academy of Sciences