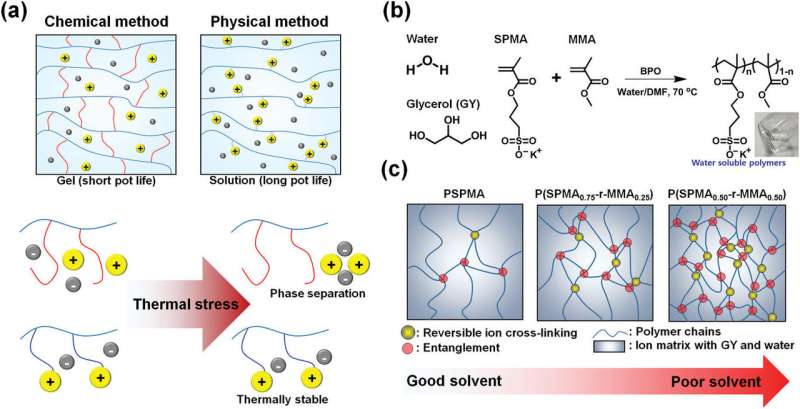

The effects of ionic side chain. a) Schematics indicating difference regarding pot life and thermal stability according to chemical and physical methods. b) Scheme for P(SPMA-r-MMA)s and water solubility. c) Physical cross-linking (reversible ion cross?linking and entanglement) regarding affinity with solvent in the gels. Credit: Taiho Park(POSTECH)

Recent outbreaks of the novel coronavirus have emphasized the importance of quarantine and prevention more than ever. When monitoring changes in our body, body temperature is measured first, so it is very important to measure the temperature accurately and promptly. With this regard, a research team recently developed a stretchable and deformable polymer ionic conductor to realize a thermal sensor that could measure body temperature by simple contact, such as wearing clothes or shaking hands, and an actuator that could control movement of artificial muscle.

Prof. Taiho Park and his student, Junwoo Lee from the POSTECH Department of Chemical Engineering developed a thermally stable and flexible ionic conductor by using water solvent in a joint research effort with Nanyang Technological University for the first time. Their research accomplishment was published in the latest issue of the online version of Advanced Materials, the most renowned journal in the field of materials science.

Various materials for ionic conductors have been developed, however with limitations to overcome. A semiconductor device used in most electronic devices has a problem with diminished electronic performance due to mechanical stress when it is stretched or contracted. Also, rubber with nano-silver particles requires a difficult process and is not transparent. Hydrogel ions are easily dried out and lose their flexibility.

To solve these problems, the research team designed a P (SPMA-r-MMA) polymer with different ratios of ionic side chains and chemically linked ionic materials with polymer chains. When making an ionic conductor, it is critical to have a solution process at room temperature. So, the newly developed polymer ionic conductor was processed with water as a solvent and covered with thin film. The process was much simpler than the conventional ones and it did not use toxic solvents and could be mass-produced.

The chemically linked ionic conductor was thermally stable and stretchable. Also, it was self-healable in that it could recover its structure when ripped or broken. The research team used this ionic conductor to realize an actuator thermally stable up to 100°C and a flexible thermal sensor applicable to the body for the first time.

Junwoo Lee who performed the research said, "This is the first example of developing a polymer ionic conductor, which is used in a next-generation stretchable device, by facilitating a water solvent instead of a toxic chemical solvent. The polymer ionic conductor that we developed this time is stretchable, self-healable and thermally stable. For this reason, we anticipate that our research will impact greatly on the stretchable wearable electronic device industry."

More information: Junwoo Lee et al, Water‐Processable, Stretchable, Self‐Healable, Thermally Stable, and Transparent Ionic Conductors for Actuators and Sensors, Advanced Materials (2019). DOI: 10.1002/adma.201906679

Journal information: Advanced Materials

Provided by Pohang University of Science & Technology (POSTECH)