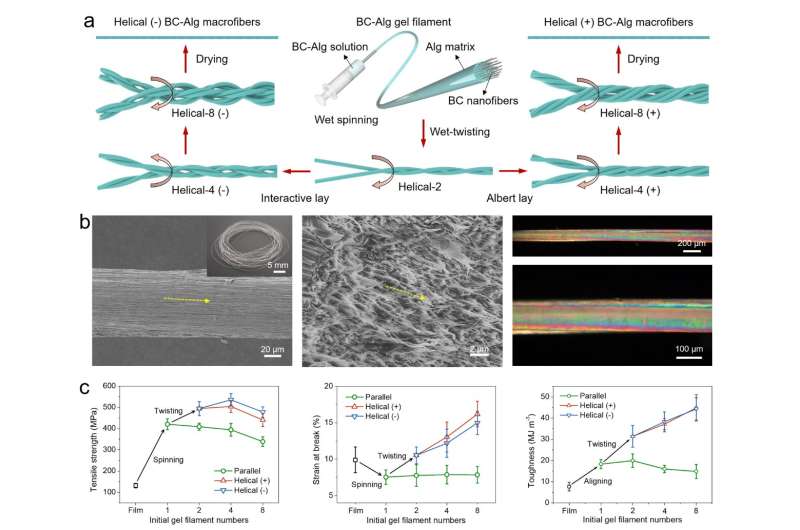

Schematic illustration of the fabrication process (a), structural characterization (b) and mechanical investigation (c) of the bioinspired hierarchical helical nanocomposite fibers. Credit: Science China Press

High-performance biomass-based nanocomposites are emerging as promising materials for future structural and functional applications due to their environmentally friendly, renewable and sustainable characteristics. Bio-sourced nanocelluloses (a kind of nanofibers) obtained from plants and bacterial fermentation are the most abundant raw materials on earth. They have attracted tremendous attention recently due to their attractive inherent merits including biodegradability, low density, thermal stability, global availability from renewable resources, as well as impressive mechanical properties. These features make them appropriate building blocks for spinning the next generation of advanced macrofibers for practical applications.

In past decades, various strategies have been pursued to gain cellulose-based macrofibers with improved strength and stiffness. However, nearly all of them have been achieved at the expense of elongation and toughness, because strength and toughness are always mutually exclusive for man-made structural materials. Therefore, this dilemma is quite common for previously reported cellulose-based macrofibers, which greatly limited their practical applications.

In a new article published in the National Science Review, Recently, a bionics research team led by Prof. Yu Shuhong from the University of Science and Technology of China (USTC) sought an inspiration to solve this problem from biological structures. They found that the widespread biosynthesized fibers, such as some plant fibers, spider silk, and animal hairs, all have some similar features. They are both strong and tough, and have hierarchical helical structures across multiple length scales with stiff and strong nanoscale fibrous building blocks embedded in soft and energy dissipating matrices.

Inspired by these structural features in biosynthesized fibers, they presented a design strategy to make nanocellulose-based macrofibers with similar structural features. They used bacterial cellulose nanofibers as the strong and stiff building blocks, sodium alginate as the soft matrix. By combining a facile wet-spinning process with a subsequent multiple wet-twisting procedure, they successfully obtained biomimetic hierarchical helical nanocomposite macrofibers, and realized impressive improvement of their tensile strength, elongation and toughness simultaneously as expected.

This achievement certifies the validity of their bioinspired design and provides a potential route for further creating many other strong and tough nanocomposite fiber materials for diverse applications.

More information: Huai-Ling Gao et al, Bioinspired hierarchical helical nanocomposite macrofibers based on bacterial cellulose nanofibers, National Science Review (2019). DOI: 10.1093/nsr/nwz077

Provided by Science China Press