June 27, 2019 feature

Printing liquid metals in three-dimensional structures

In a recent study on materials science and nanomedicine, Young-Geun Park and co-workers at the departments of Nanoscience, Nanomedicine and Materials Science and Engineering in the Republic of Korea developed an unconventional 3-D printing approach. The scientists engineered a high-resolution, reconfigurable 3-D printing strategy using liquid metals to form stretchable, 3-D constructs. Using the technique, they formed a minimum line width of 1.9 µm using direct printing and printed patterns for reconfiguration in to diverse 3-D structures while maintaining pristine resolutions.

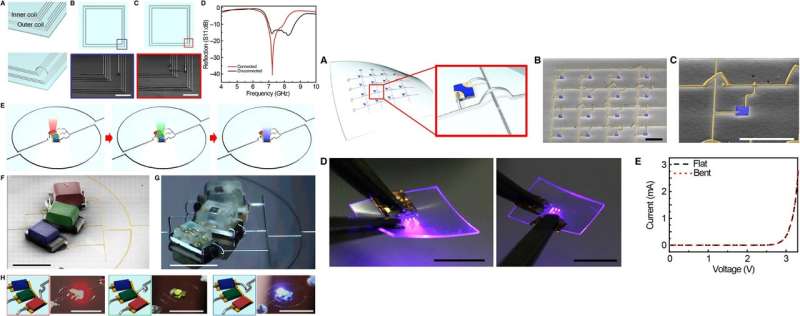

They performed reconfigurations many times to generate a thin oxide interface and preserve electrical properties of the material under ambient conditions. The free-standing features could be encapsulated in stretchable, conformal configurations. Park et al. demonstrated applications in the form of reconfigurable antenna, tunable by changing geometries and reversibly movable interconnections to use the constructs as mechanical switches. The free-standing 3-D structures were advantageous to minimize the number and space between interconnections for higher integration, as seen with microLED arrays. The results are now published on Science Advances.

Advanced technologies that form 3-D conductive structures with high-resolution, high aspect ratios and minimal error of displacement are important to increase device integrity. Device deformability is a key consideration for free-form electronics, including stretchable electronics, wearable electronics, soft actuators and robotics. These electronic devices typically require conformation with movable, arbitrary shapes such as joints or arms, or the soft surfaces of living organisms. Realizing such stretchable devices with conventional materials such as silicon are a challenge due to their brittleness. Materials scientists have therefore developed diverse conductive materials with excellent stretchability in the form of wavy thin metals, metallic networks and elastomeric composites, yet these processes are unable to form scalable 3-D structures. In addition, 3-D printed, and thermally annealed metals are relatively stiff and rigid causing damage to soft, tissue-like substrates.

Comparatively, liquid metals such as eutectic gallium-indium alloy (EGaIn) or gallium-indium-tin alloy (Galinstan) are intrinsically stretchable, with low toxicity and minimal volatility for superb electrical conductivity—comparable to solid metals. Direct ink printing with a nozzle can form free-standing 3-D structures at room temperature by stacking droplets of liquid metal upon one another but the resulting resolution is not suited to build electronic devices. In the present work therefore, Park et al. report a high-resolution printing method with liquid metal for its direct reconfiguration into 3-D electrode patterns through a nozzle, under ambient conditions.

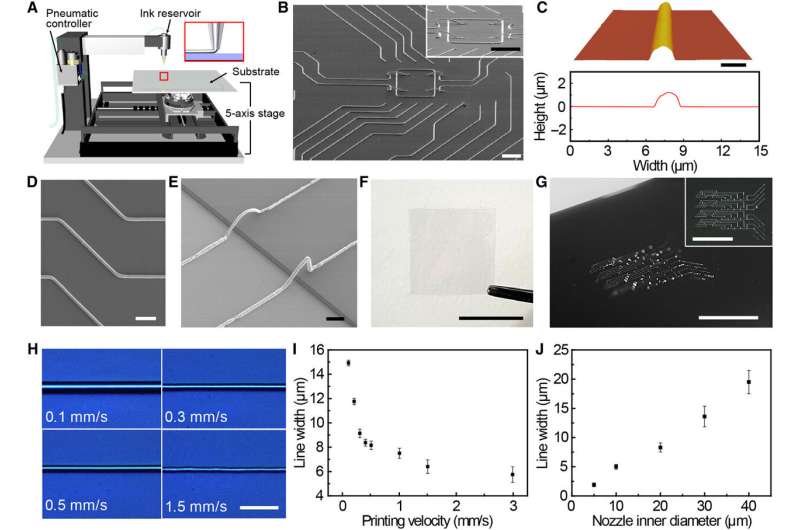

In the experimental setup, Park et al. connected a nozzle to an ink reservoir or pressure controller. The materials scientists used EGaIn (75.5 percent gallium and 24.5 percent indium alloy by weight) as the ink and controlled the distance between the nozzle tip and polymer substrate to deliver the ink. Using scanning electron microscopy (SEM), they viewed the EGaIn pattern printed with complex 2-D and 3-D geometries and used the technique to print more diverse patterns such as interconnects of electric circuits with high resolution.

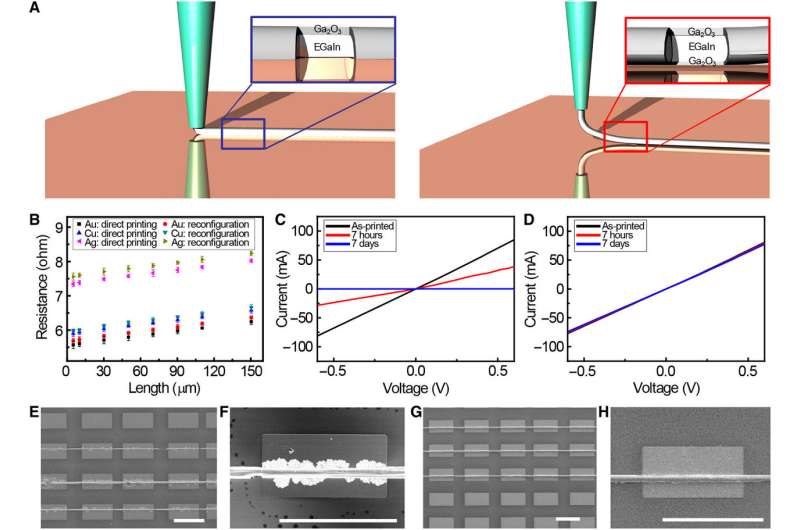

After directly printing EGaIn through a nozzle, the scientists lifted the nozzle tip for its relocation to the desired position of the substrate to continue printing. The fracture energy of the oxide skin connected the nozzle tip as a "rope" during lift-off. Park et al. measured the maximum velocities for different diameters of filaments to demonstrate different examples and formed 2-D and 3-D features with repeatable reconfiguration. During the process of reconfiguration, the scientists could lift-off a preprinted filament upright from a substrate without fracturing the construct. The observed stable electrodes could withstand electrical load to become increasingly integrated and miniaturized in electric devices. To verify the suitability of EGaIn electrodes as interconnects, Park et al. conducted electrical breakdown tests thereafter.

When they applied DC or AC bias to monitor electrical breakdown, the temperature too increased in the experimental setup affecting the mechanical stability of the EGaIn 3-D features. The constructs maintained their initial free-standing 3-D structure without structural collapse at 5000C for 30 minutes. After repeated heating and cooling at room temperature, the oxide skin of the 3-D feature slightly wrinkled due to thermal expansion between the oxide shell and EGaIn core. Park et al. tested the electrical contact of direct-printed and reconfigured liquid metals and measured the dependence of total resistance on the length of the printed channel to show that the resistance of EGaIn patterns significantly increased with time under ambient conditions.

As a proof-of-principle of the reconfigurable electronics developed in the present work, Park et al. demonstrated the formation of a reconfigurable antenna with ability to modify its resonance frequency and radiation properties by changing its geometry. For this, the scientists formed a dual coil antenna structure on a glass slide by directly printing EGaIn. During reconfiguration, EGaIn formed a 3-D bridged interconnect, whose resonance frequency the scientists first determined, followed by their use to selectively operate three different light-emitting diodes (LEDs) with red, green and blue light emissions. The reconfigurable, free-standing interconnect maintained its resistance to reliably operate all LEDs at 3V during repeated detachment and connection of multiple reconfiguration steps.

The free-standing 3-D interconnects formed using the process of reconfiguration were advantageous to build cross-geometries in a single XY plane, instead of using multiple layers to thereby prevent unwanted electric contact. For this, Park et al. demonstrated both transverse and longitudinal interconnects of EGaIn for a 4 x 4 array of microLEDs on a flexible polymer film to prevent short circuiting. Using the method, Park et al. minimized the number of interconnections integrated in a miniature device, as the 3-D pattern could efficiently minimize the number and space of interconnections.

In this way, Young-Geun Park and co-workers demonstrated high-resolution 3-D printing using liquid metal and showed its application for stretchable 3-D integrations that are difficult to achieve with conventional engineering. Compared to existing 3-D printing techniques, this method can form fine, free-standing 3-D structures of electrodes with reconfigurable patterns. As an example, Park et al. engineered a reconfigurable antenna capable of modifying its resonance frequency via geometric changes. They also presented reversibly movable 3-D interconnections as mechanical switches that could facilitate higher compact integration in miniaturized devices. The scientists expect the high-resolution 3-D reconfiguration method to offer a promising new additive manufacturing strategy for highly integrated and stretchable next-generation electronic devices.

More information: Young-Geun Park et al. High-resolution, reconfigurable printing of liquid metals with three-dimensional structures, Science Advances (2019). DOI: 10.1126/sciadv.aaw2844

B. Y. Ahn et al. Omnidirectional Printing of Flexible, Stretchable, and Spanning Silver Microelectrodes, Science (2009). DOI: 10.1126/science.1168375

Sihong Wang et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array, Nature (2018). DOI: 10.1038/nature25494

Journal information: Science Advances , Science , Nature

© 2019 Science X Network